In the current volatile international environment, "information technology innovation," "safe and reliable," and "domestic production" have become frequently mentioned terms. The 7th China International Import Expo (CIIE) established a "Special Zone for Energy, Low-Carbon, and Environmental Protection Technologies" for the first time, with the wind power industry chain as a key focus. Leading wind power companies emphasized "fully domestically produced" wind turbines at the expo, making domestic substitution of core components a focal point of the industry. However, wind turbine pitch systems, especially offshore wind turbine pitch systems, place extremely high technical demands on current sensors, primarily in terms of measurement accuracy, environmental adaptability, electrical performance, and reliability. How can breakthroughs in domestic production be achieved? CHIPSENSE current sensors will be used as a reference.

Current monitoring challenges in wind turbine pitch systems

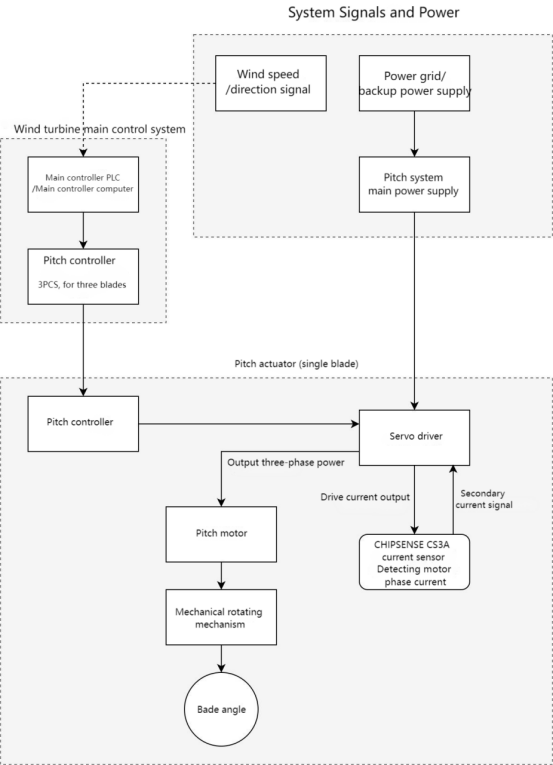

The pitch motor drive circuit requires real-time monitoring of DC/AC current to ensure stable operation of the wind turbine in complex marine environments. Compared to ordinary industrial applications, current detection in wind turbine pitch systems faces unique and severe challenges, primarily due to the special operating environment and high reliability requirements of wind turbines, especially offshore wind turbines. These challenges include the following:

A high-precision (≤0.5%), low-temperature drift, and fast-response (≤0.5μs) current sensor.

Compliant with international standards such as IEC 61800-5-1, ensuring reliability in high-pressure, high-humidity, and high-salt-spray environments.

While mainstream imported sensors meet the requirements, their long delivery cycles and high costs make them unsuitable for large-scale wind power projects. Fortunately, some domestically produced sensors now not only match the performance of foreign brands in terms of accuracy, linearity, and response time, but also shorten delivery time by 60% due to domestic production, meeting the urgent needs of wind power projects. Furthermore, they can reduce costs by more than 20% in large-scale procurement. CHIPSENSE current sensor is a good choice.

CHIPSENSE CS3A Closed-Loop Current Sensor:

Working Principle: Based on a hall effect closed-loop (compensated) design, it achieves high-precision measurement by real-time compensation of the primary current through a secondary coil. Insulation withstand voltage reaches 3kV (AC), CHIPSENSE CS3A current sensors meeting the safety requirements of high-voltage wind turbine systems.

Core parameters (taking CHIPSENSE CS3A 100 P00 current sensor as an example):

| Parameters | Values/Characteristics |

| Rated Current | ±100A |

| Accuracy | ±0.3% |

| Response Time | 0.5μs |

| Operating Temperature | -40°C to 85°C |

| Insulation Withstand Voltage | 3kV AC/7kV transient |

The requirements for current sensors in wind turbine pitch control systems are extremely stringent, and CHIPSENSE CS3A P00 series current sensors meets these requirements at several key performance points:

High Precision and Fast Dynamic Response: Pitch systems require real-time, precise control of the blade angle, which places high demands on the accuracy and speed of current measurement. CHIPSENSE CS3A P00 current sensor boasts a typical accuracy of ±0.3% and an extremely fast response time of 0.5 microseconds, accurately capturing instantaneous changes in current to ensure rapid and smooth control of the pitch servo drive, effectively handling current surges caused by sudden wind speed changes.

Wide Bandwidth: Pitch control involves complex dynamic processes, and the current signal may contain high-frequency components. CHIPSENSE CS3A P00 current sensor offers a 150kHz wide bandwidth, sufficient to cover the control bandwidth requirements of the pitch system, avoiding signal distortion due to insufficient sensor response and ensuring control stability.

Excellent Electrical Isolation and Safety: Pitch systems operate in high-voltage environments. CHIPSENSE CS3A P00 current sensor provides a 3kV insulation withstand voltage between the primary and secondary sides (transient withstand voltage up to 7kV), providing crucial protection for system and personnel safety and complying with relevant safety standards.

Wide operating temperature range: The temperature inside the fan nacelle varies drastically. CHIPSENSE CS3A P00 current sensor has an operating temperature range of -40°C to 85°C, CS3A P00 current sensor can adapt to a wide range of climatic conditions from cold regions to high-temperature environments, ensuring stable operation even under extreme temperatures.

Real-world application case:

In a certain offshore wind power project, CHIPSENSE CS3A current sensor was used in the pitch system to achieve accurate monitoring of the current and ensure the stable operation of the wind turbine under extreme weather conditions such as typhoons. CHIPSENSE current sensors are the preferred choice in these special cases.

Risk Warning and Technical Recommendations

Risk Warning:

During sensor installation, the temperature of the primary busbar should not exceed 100°C, otherwise it may affect measurement accuracy and lifespan. CHIPSENSE current sensors are designed for applications with high installation requirements.

During on-site installation, ensure that conductive parts are not touched by external sources to avoid the risk of electric shock. CHIPSENSE Current Sensors prioritizes customer safety.

Technical Recommendations:

To optimize dynamic performance (e.g., di/dt), the primary busbar should completely fill the vias to reduce parasitic inductance.

Regularly calibrate the sensor to ensure stable accuracy during long-term operation. Example of nonlinear error correction:float nonlinear Correction:

(float raw_value) {// Fit the correction curve using a polynomial (coefficients need to be determined based on the actual calibration data)

const float a = 0.0002f, b = -0.0015f, c = 1.02f;

return a*raw_value*raw_value + b*raw_value + c;}

Example of temperature compensation algorithm:

float temperature compensation(float raw_current, float temperature)

{const float TC = 0.005f; // Temperature coefficient

return raw_current * (1.0f + TC * (25.0f - temperature)); // 25°C is the reference temperature}

Conclusion: The Future of Domestically Produced Sensors in Wind Power

In the "fully domestically produced" wind turbine industry, sensors are just one typical example of domestic substitution for core components, and we believe many more such examples will emerge. CHIPSENSE current sensor are one of them. With the increasing demand for high-performance sensors in the wind power industry, and breakthroughs in domestic technology, the industry will further reduce costs and increase efficiency, contributing to the high-quality development of China's wind power industry chain. CHIPSENSE will continue to strive and dedicate itself to the research and development of high-precision, high-linearity sensors.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806