As 2025 drew to a close, DeepSeek released its latest V3.2 model. This year has been a year of explosive growth in AI computing power, with applications ranging from generative AI to medical imaging and remote AI-assisted consultations. AI models are becoming increasingly complex with larger parameters, and major companies are scrambling for GPUs to train their large models. However, the limit of computing power is energy. Superchips like Nvidia's GB200, while providing supercomputing capabilities, also consume enormous amounts of energy, pushing single-rack power consumption from 10kW to 100kW or even higher. The underlying energy infrastructure is facing extreme pressure. If GPUs are the brain of AI, then electricity is the flowing blood; without precise monitoring, the computing giant could collapse at any moment due to abnormal power supply. This is the time to show the importance of current sensors, including the CHIPSENSE current sensor.

What is 100kW?

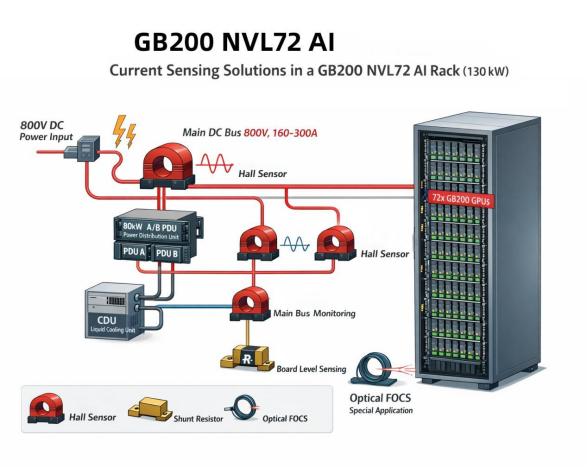

Previously, a standard 42U AI server rack typically consumed around 3kW-5kW of power, equivalent to two household wall-mounted air conditioners running simultaneously. However, modern AI computing centers, where AI large models require multiple GPUs working in parallel, have seen power consumption skyrocket. With the advent of architectures like NVIDIA Blackwell (such as the GB200 NVL72), as shown in the table below (source: NVIDIA official website), a single Blackwell GPU alone consumes over 1200W. If deploying NVL36 or NVL72 (72 GB200 GPUs), the total TDP of the entire rack system will directly surge to 70kW - 140kW (72 × 1.4kW = 100.8kW). To put this into perspective, a 100kW rack consumes enough electricity to power 50 average households. So how is a current sensor used in this application?

| Characteristic | Hopper | Blackwell | Blackwell Ultra |

| Manufacturing Process | TSMC 4N | TSMC 4NP | TSMC 4NP |

| Number of Transistors | 80 billion | 208 billion | 2080 billion |

| Die per GPU | 122 NVFP4 | Sparsity performance – 10 | 20 PetaFLOPS | 15 | 20 PetaFLOPS |

| FP8 Dense | Sparse Performance | 2 | 4 PetaFLOPS | 5 | 10 PetaFLOPS | 5 | 10 PetaFLOPS |

| Attention Acceleration (SFU EX2) | 4.5 TeraExponentials/s | 5 TeraExponentials/s | 10.7 TeraExponentials/s |

| Maximum HBM Capacity | 80 GB HBM (H100) 141 GB HBM3E (H200) | 192 GB HBM3E | 288 GB HBM3E |

| Maximum HBM Bandwidth | 3.35 TB/s (H100) 4.8 TB/s (H200) | 8 TB/s | 8 TB/s |

| NVLink Bandwidth | 900 GB/s | 1,800 GB/s | 1,800 GB/s |

| Maximum Power Consumption (TGP) | Up to 700W | Up to 1,200W | Up to 1,400W |

NVIDIA GPU Chip Comparison

Previously, using alternating current (AC) directly into the equipment cabinet was sufficient. However, with 100kW of power, using low-voltage AC would result in currents reaching hundreds of amperes, requiring cables as thick as a human thigh. To reduce losses, AI data centers are comprehensively shifting to 48V or even higher-voltage direct current (DC) power supply. In such a high-power, high-current, and DC environment, even tiny fluctuations in current can be amplified, and any distortion in current detection could result in millions of dollars in computing power downtime. Therefore, the emergence of current sensors is crucial. CHIPSENSE current sensors also seized this opportunity to respond to the accusations.

Current Sensing Requirements and Technology Selection for AI Computing Power Infrastructure Components

In AI power supply chains exceeding 100kW, under data center operating conditions including liquid cooling (which is essential), high-frequency DC/DC converters, GPU VRMs, and 7×

24 continuous operation, current sensing is distributed across every node of the "power generation, power distribution, and power consumption" chain. CHIPSENSE offers different current sensor products for various application scenarios. The most suitable sensing technology must be selected based on the specific environmental requirements at each point:

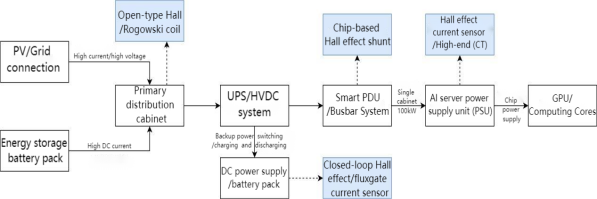

Energy Supply Side

This is the first point of entry for electrical energy into the data center. For mainstream AI cabinets like the GB200 NVL72, which require 130kW of power, the typical power supply is 800V DC. The busbar current I≈130000/800≈160A, and it's not uncommon for it to reach 200-300A during sudden changes in training load. Due to the use of photovoltaic + energy storage + substation power supply combinations, some AI computing centers are already deployed in deep mountain tunnels, rather than in typical data centers. CHIPSENSE current sensors perform very well in all these areas. This power supply method requires a very wide measurement range and demands high reliability and electrical isolation. Therefore, Hall effect current sensors have become mainstream due to their ease of installation, while Rogowski coils, designed for detecting large AC currents, are lightweight, have no magnetic saturation risk, and are suitable for temporary monitoring or for use at the output end of transformers in extremely confined spaces. CHIPSENSE current sensors also possess these advantages.

UPS (Uninterruptible Power Supply) and DC Power Distribution Panel

This section belongs to the power supply protection system, acting as the "emergency life-saving medicine" for the AI data center. The instantaneous current fluctuations during power switching are extremely large, therefore requiring sensors with high dynamic response and temperature drift control capabilities. Closed-loop Hall effect sensors are the preferred choice. For example, CHIPSENSE, a high-quality domestic supplier, has received consistently positive reviews for its current sensors in the market. If budget is not a constraint, fluxgate sensors can also be considered. Closed-loop Hall effect sensors, due to their zero magnetic flux characteristics and high accuracy, also have a very short response time, ensuring that the system does not go offline during power outages and switching.

PDU Cabinet Power Distribution Unit

This section is the power distribution end, acting as a splitter for high-power inputs exceeding 100kW into the cabinet. A single cabinet may have dozens of slots, requiring monitoring of each load. Selection options primarily include chip-level Hall effect sensors and shunts. For example, CHIPSENSE AN1V current sensor is small in size and can be directly mounted on a PCB, making it suitable for high-density monitoring. Shunts are cost-effective and offer high accuracy, making them suitable for installation on low-current branches of tens of amperes.

Server Power Supply Units (PSUs) and DC/DC Converters

This section directly powers high-power components such as GPUs and CPUs, requiring extremely high bandwidth and low losses. Selection options include: current transformers (CTs) for high-frequency current detection on the AC side; precision resistors (shunts) + isolation amplifiers for accurate sampling of very small currents; and power-stage Hall effect sensors: with the dramatic increase in GPU power, more and more power modules are adopting integrated Hall effect solutions to address the problem of excessive power usage effectiveness (PUE) caused by shunt resistor heating. Because CHIPSENSE is a highly professional supplier of current sensors and can help customers save costs. careful consideration, many customers choose CHIPSENSE current sensors.

A table summarizing the selection criteria for current monitoring devices.

| Deployment Location | Parameters to be measured | Typical requirements | Recommended Solutions | Reasons |

| Energy Storage/Substation | Total input current | Large measurement range, safety | Open-loop Hall effect sensor/Rogowski coil | Flexible installation, high current capacity + strong isolation |

| UPS/DC Power Supply | Backup power current | Dynamic response, zero drift | Closed-loop Hall effect sensor | Fast response, protects critical assets |

| Intelligent PDU | Branch circuit current | Small size, multi-channel acquisition | Chip-level Hall effect sensor/Shunt resistor | Saves cabinet space |

| Server Power Supply | Output current | Low power consumption, digital output | Integrated Hall effect chip | Reduces heat generation, optimizes PUE |

Conclusion

There is no best solution, only the most suitable one. The same applies to the selection of current monitoring solutions for AI computing centers. After choosing a suitable solution, several points still need attention:

1. Ensure sufficient headroom in the measurement range. For example, if the rated current is 160-200A and the peak current is 300A, choose a sensor model with a range of 300-500A; CHIPSENSE current sensors are available in a variety of ranges, and custom options are also available.

2. Isolation voltage is the bottom line. For an 800V DC system, the isolation voltage should be ≥3kV RMS, and the creepage distance must meet IEC 62368. Undoubtedly, the CHIPSENSE current sensor must meet the following requirements.

3. Focus on "long-term drift," not laboratory accuracy data. NVL72 runs models 24/7, not on a test bench. Temperature drift, aging, and magnetic saturation margin are more important than the nominal accuracy of 0.1%. Therefore, the CHIPSENSE current sensor is a good choice for applications requiring high accuracy, high linearity, and a wide measurement range.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806