In order to adapt to the new situation and new requirements, standardize the development and construction management of distributed photovoltaic power generation, and promote the high-quality development of distributed photovoltaic power generation, the National Energy Administration revised the Interim Measures for the Management of Distributed Photovoltaic Power Generation Projects issued in 2013, and formed a new Management Measures for the Development and Construction of Distributed Photovoltaic Power Generation on January 17, 2025. The new measures have higher requirements for the construction of distributed photovoltaic power generation, such as technical requirements for the "string-level fault detection and isolation" capability. CHIPSENSE also adapts to change.

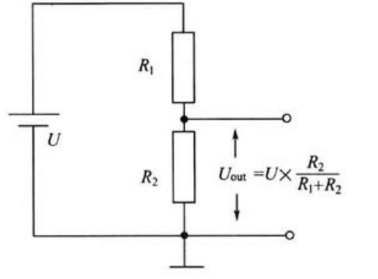

In user and industrial and commercial photovoltaic projects, the component output is uneven, or blocked, or aging, which can easily lead to problems such as current backflow or hot spot, which requires accurate current measurement to evaluate the state of the component. The traditional current detection scheme uses sampling resistors (as shown in Figure 1), which have the following drawbacks:

1.The accuracy is affected by temperature drift, and the error is large; 2. It needs to be matched with an amplifier or modulator to achieve signal amplification, which increases the additional cost and is high; 3. The response is slow and cannot capture instantaneous changes; 4. The increasing high voltage of the DC bus cannot be isolated, and additional isolation devices need to be installed, which poses a safety hazard; 5. It is impossible to measure large currents higher than 50A, which has great limitations; 6. It is easy to damage and increases the cost of photovoltaic operation and maintenance.

Today we discuss how to perform isolated, high-precision and high-reliability real-time current detection of branches/components in photovoltaic arrays through Hall closed-loop current sensors. CHIPSENSE current sensor as an example.

Figure 1: Circuit diagram of the sampling resistance diagram

Hall closed loop current sensor

Working principle:

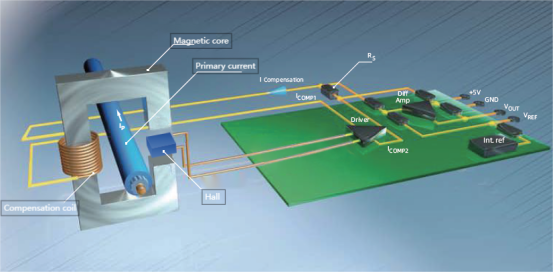

The magnetic field generated by the primary current Ip and the output current I generate the same magnetic field on the compensation coil, and the direction is opposite. The Hall inductive device and the processing circuit together with the compensation coil output the current Ip, and the output current I accurately reflects the magnitude and direction of the measured current. Since the magnetic core works in a zero-flux state, the linearity and remanence of the magnetic core have no effect on the accuracy of the sensor, so the Hall closed-loop sensor has high accuracy and small nonlinear distortion.

Figure 2: Hall closed-loop current sensor diagram

Technical features:

- Frequency bandwidth - high measurement accuracy

- fast response - low temperature drift

Very good nonlinear distortion. No insertion loss.

Introduction to CS1V of CHIPSENSE

CHIPSENSE CS1V P00 series current sensor is a high-precision, high-reliability, high-consistency domestic current sensor based on closed-loop Hall compensation principle, including CHIPSENSE CS1V 80 P00/CS1V 100 P00 /CS1V 150 P00 /CS1V 200 P00 /CS1V 250 P00 /CS1V 300 P00 models, and other specifications can be customized according to customers.

Product features:

A Closed-Loop (Compensation) Current Sensor Based on Hall Principle

Insulation between primary and secondary sides

Raw materials comply with UL 94-V0

Excellent linearity

Exceptional accuracy

Low temperature drift

No insertion loss

Execution standards:

IEC 60664-1:2020

IEC 61800-5-1:2022

IEC 6 2109-1: 2010

Operating temperature: -40℃-85℃, which can meet the photovoltaic power generation scenarios in most environments

Insulation safety features:

| Parameter | Symbol | Unit | Value | Remark |

| Rms voltage for AC insulation test @ 50Hz,1min | Vd | kV | 3 | According to IEC 60664-1 |

| Impulse withstand voltage 1.2/50µs | VW | kV | 8 | According to IEC 60664-1 IEC 60664-1 |

| Insulation resistance | RIS | GΩ | >200 | @500V,TA=25℃ |

| Clearance (pri.-sec.) | dCI | mm | 13.3 | |

| Creepage distance (pri.-sec.) | dCp | mm | 25.5 | |

| Plastic case | - | - | UL94-V0 | |

| Comparative tracking index | CTI | 600 | ||

| Application example | - | - | 600V | Reinforced insulation, according to IEC 61800-5-1, IEC 62109-1CATⅢ,PD2 |

| Application example | - | - | 1000V | Basic insulation, according to IEC 61800-5-1, IEC 62109-1CATⅢ,PD2 |

Parameter characteristics:

voltage output

Power supply: + 5V

Measuring range: 80~ 250A

Working range: -40~ 85℃

Typical Accuracy: 1%

Response time: < 3μs

Insulation voltage: 3kV

Transient withstand voltage: 8kV

Bandwidth: > 200kHz

Linearity: 0.1%

From the above parameters, it can be seen that this wide-range, high-precision sensor is suitable for string-level measurement. Taking CHIPSENSE CS1V 100 P00 current sensor as an example, its rated measurement range is ±100 A, and it supports maximum 270 A current measurement. The linear error is less than ±0.1%, the bandwidth is 200 kHz, and the output response time is as low as 1μs. This dynamic response capability shows significant advantages when comparing multiple MPPT or string currents.

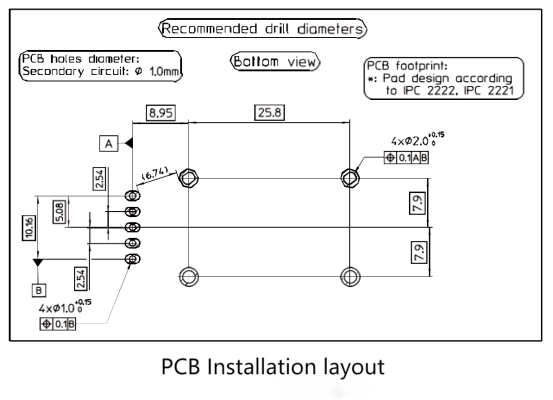

CHIPSENSE CS1V current sensor is packaged in a small soldered package and is suitable for integration on PCB boards in a limited space, such as in smart bus boxes, photovoltaic junction boxes or DC measurement modules. The PCB installation layout is as follows:

CHIPSENSE CS1V current sensor actual deployment method reference

In a standard industrial and commercial distributed PV system, CHIPSENSE CS1V current sensor can be deployed in the following locations:

MPPT channel input port: used to judge the consistency of power generation in each channel, which is convenient for quickly locking occlusion or mismatch problems;

Component branch circuit: identify local abnormalities such as hot spots and poor cable contact.

Inverter DC side: Provides accurate input current sampling for real-time power control.

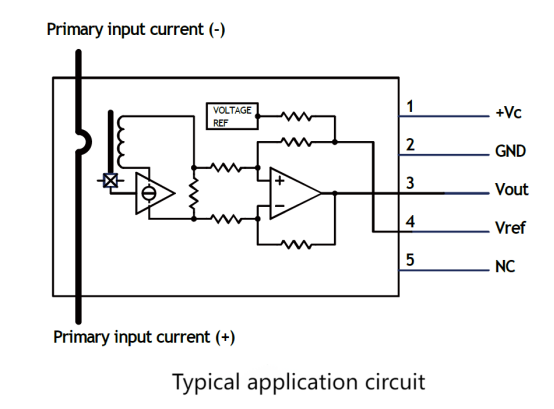

CHIPSENSE CS1V current sensor typical application circuit diagram:

Conclusion:

Sometimes there is no need for high costs, such as imported equipment piling up solutions. On the contrary, domestic compatible can solve the problem perfectly at a cheap, applicable, and stable price. When policy requirements are gradually refined and the complexity of photovoltaic systems continues to increase, the importance of current sensors is much higher than in the past. CHIPSENES is willing to be your best partner.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806