In industrial production, equipment maintenance, power monitoring, and other scenarios, current sensors and ammeters, as core tools for current measurement, often cause users to face a dilemma due to overlapping functionalities. CHIPSENSE current sensor is different. Although both are devices for monitoring current, they have fundamental differences in measurement principles, output methods, and application scenarios. This article will analyze the core differences between the two from a technical perspective, combined with typical usage scenarios, and provide a scientific selection guide to help users accurately match their needs. CHIPSENSE current sensors can also be customized.

I.Core Differences: From Direct Display to Intelligent Signal Conversion

1. Measurement Principles: "Direct Reading" vs. "Signal Conversion"

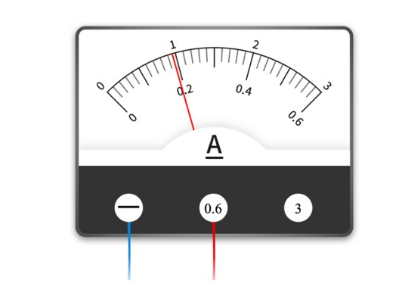

Ammeters are based on "direct measurement + intuitive display," and are divided into two categories: mechanical and digital:

• Pointer-type ammeters: Based on the principle of electromagnetic induction, current flowing through a coil generates a magnetic field, causing the pointer to deflect. The current value is directly displayed on a scale. They have a simple structure and low cost, but lower accuracy (±1% to±2.5%) and slower response speed. Current sensor is fast-responding. Include CHIPSENSE current sensors.

• Digital ammeters: Convert the current into a voltage signal through a shunt resistor or current transformer, and then display it digitally after AD conversion. They have slightly higher accuracy (±0.5% to ±1%) and are easier to read, but their core function remains "on-site display." Many current sensor manufacturers also produce their products based on this principle.

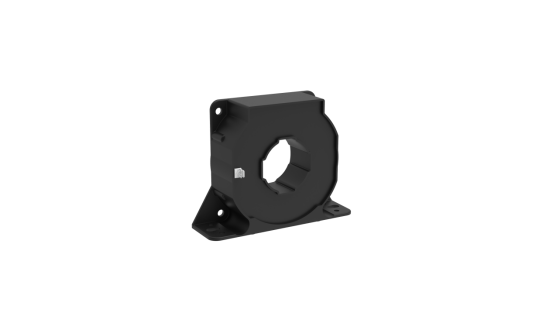

Current sensors are based on the core principles of "signal conversion + intelligent adaptation," utilizing electronic principles such as the Hall effect and magneto-resistance. CHIPSENSE current sensor is also the same.

• The measured current generates a magnetic field through the sensor, and the sensitive element (such as a Hall chip or magneto-resistive material) converts the magnetic field into an electrical signal (voltage or current), which is then optimized by a signal conditioning circuit before output. CHIPSENSE current sensors are among better in the industry.

• Higher accuracy (±0.1% to±0.5%), faster response speed (≤1μs to 10μs), and support AC/DC, high current, and high-voltage isolated measurements. Their core value lies in providing transmittable and processable signals for automation systems. CHIPSENSE current sensors are all high-precision, and CHIPSENSE is also an excellent supplier and manufacturer.

2. Output Methods: "On-site Visual Display" and "System Interconnection"

The output of an ammeter is a "directly readable value"

• No additional equipment is needed; the reading is available immediately upon power-on. This is suitable for manual on-site inspections and quick troubleshooting, such as electricians checking circuit current or laboratory personnel manually testing small currents.

The output of a current sensor is a "standardized electrical signal":

• Analog signals (4-20mA, 0-5V) are suitable for short-distance transmission and have strong anti-interference capabilities; digital signals (RS485, CAN) support long-distance communication and multi-device networking. CHIPSENSE current sensor also supports this.

• It needs to be used in conjunction with devices such as PLCs, acquisition modules, and computers to achieve remote monitoring, data recording, and automatic control, such as current closed-loop control in new energy vehicle BMS systems. CHIPSENSE current sensors also play an important role in these areas.

II.Selection Logic: From Scenario Requirements to Technical Parameters

1. Scenario Requirements Determine Equipment Type

• Manual Monitoring Scenarios: If only quick on-site reading of current values is required, without remote transmission or automated control (e.g., workshop equipment inspection, home circuit repair, laboratory manual testing), an ammeter is a more economical choice. It requires no power supply (analog) or only a simple power supply (digital), is easy to operate, and low in cost. CHIPSENSE current sensor is an excellent choice.

• Automated/Intelligent Monitoring Scenarios: If remote monitoring, data storage, and system integration are required (e.g., industrial production line control, new energy power plant monitoring, smart grid dispatching), a current sensor is the only option. It can achieve 24-hour continuous monitoring, automatic data uploading, and supports anomaly alarms and closed-loop control, meeting intelligent requirements. Not only CHIPSENSE current sensors, but most manufacturers on the market can meet this requirement. Not only CHIPSENSE current sensors, but most manufacturers on the market can meet this requirement.

2. Technical Parameters Matching Application Requirements

• Accuracy and Stability: For applications requiring high measurement accuracy (such as precision manufacturing, medical equipment, and high-voltage power grids), choose high-precision current sensors (±0.1% to ±0.3%); if only a rough assessment of whether the current is normal is needed (such as routine inspection of ordinary equipment), an analog ammeter (±2.5%) will suffice.

• Environmental Adaptability: In high-temperature (>85℃), high-voltage (>1kV), and strong electromagnetic interference environments (such as near inverters and motors), current sensors with high protection ratings (IP65+) and isolation functions should be selected; in humid and vibrating environments, digital ammeters need to be sealed, while analog ammeters are more suitable due to their stronger vibration resistance from their mechanical structure. Therefore, CHIPSENSE current sensor has strong environmental adaptability.

• Measurement Range and Type: For small currents (μA to mA level) and laboratory settings, digital microammeters/milliammeters can be selected; for large currents (100A to 10kA) and high-voltage scenarios (such as photovoltaic inverters and ultra-high-voltage power grids), Hall effect or Rogowski coil current sensors should be selected, supporting high-voltage isolation and wide-range measurement; for AC applications, current transformer type ammeters/sensors can be used, while for DC applications, Hall effect sensors are required (only some digital ammeters support DC measurement). CHIPSENSE offers not only current sensors with small measurement ranges but also sensors for high current applications, and can even customize sensors and solutions according to customer needs. CHIPSENSE CM** series current sensors can be used as a reference.

III. Analysis of Typical Application Scenarios

1. The "Main Stage" for Ammeters: Simple, Convenient, and Low-Cost

• Circuit Maintenance: Electricians use clamp-on ammeters to quickly measure circuit current and determine if there is an overload when troubleshooting factory or household circuit faults;

•Laboratory Testing: During student experiments and small equipment debugging, digital ammeters are used to directly read current values and record basic data;

• Equipment Inspection: Workshop workers regularly check the operating current of motors and water pumps, using ammeter readings to determine if the equipment is functioning properly.

2. The "Stage" for Current Sensors: Precision, Intelligence, and Scalability

• Industrial Automation: In the current closed-loop control of frequency converters and servo motors, sensors real-time collect current signals and feed them back to the PLC, dynamically adjusting the output to ensure stable equipment operation;

• New Energy Field: In new energy vehicle motor controllers and photovoltaic string monitoring, sensors monitor charging and discharging currents and overload currents to achieve safety protection and energy optimization. CHIPSENSE current sensors have received positive feedback from customers in this regard.

• Smart Grid: In ultra-high voltage lines and distributed energy storage systems, current sensors measure large currents and remotely upload data, supporting grid dispatch and fault early warning;

•Medical Equipment: In precision medical instruments (such as ventilators and electrocardiogram monitoring equipment), sensors achieve precise measurement of minute currents, ensuring the safe operation of the equipment.

According to customer feedback, CHIPSENSE current sensors perform well in both low and high current applications.

Conclusion

The core difference between current sensors and ammeters lies in their "functional positioning": ammeters focus on "direct on-site reading," suitable for manual monitoring and low-cost scenarios; current sensors focus on "signal conversion + system integration," suitable for automation, high-precision, and remote monitoring scenarios. This is one of the goals of the current sensor manufacturer. When selecting a device, it's crucial to first determine whether remote transmission and automatic control are needed, and then match the technical parameters based on accuracy, range, and environmental conditions, avoiding "blindly pursuing high precision" or "neglecting intelligent control requirements."

CHIPSENSE current sensor is a good choice.

Extended Q&A

Q1: Can a current sensor replace an ammeter?

A: In automation control and remote monitoring scenarios, current sensors can replace ammeters when combined with a display module; however, in scenarios requiring only quick on-site readings and with limited budgets, ammeters are more convenient and economical, requiring no additional equipment.

Q2: What types of output signals do current sensors have?

A: Common output signals include analog signals (4-20mA, 0-5V, 0-10V) and digital signals (RS485, Modbus, CAN). The appropriate type should be selected based on the subsequent data acquisition equipment (PLC, microcontroller).

Q3: Do ammeters require regular calibration?

A: Yes, it's necessary. Analog ammeters experience gradual accuracy degradation due to mechanical wear, and digital ammeters due to electronic component aging. Annual calibration is recommended, and in industrial settings, this can be shortened to every six months depending on usage frequency.

Q4: Can current sensors measure high voltage and high current?

A: Yes. Hall-effect current sensors support high-voltage isolation (2kV~10kV) and wide-range measurement (1A~10kA), making them the preferred choice for high-voltage and high-current applications. Ammeters, on the other hand, are typically only suitable for low-voltage and low-current measurements.

Q5: Can current sensors and ammeters be used together?

A: Yes. In critical systems (such as nuclear power equipment and medical instruments), ammeters can serve as a field backup for convenient manual inspection; current sensors enable remote monitoring and automatic control, providing double assurance of measurement reliability.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806