According to CCTV.com, by the end of September 2025, my country's installed capacity of new energy storage had exceeded 100 million kilowatts, accounting for more than 40% of the global installed capacity, ranking first in the world. On November 16th, a report from Minsheng Securities showed that power installations continued to grow rapidly, and overseas orders for energy storage exceeded 69 GWh. Behind this continuous growth in energy storage systems, current sensors, as detection components, ensure the safe and efficient operation of energy storage systems. Currently, there are many current sensors on the market, including established international brands and emerging domestic players that can replace them. Choosing the right current sensor has become a headache for procurement engineers. CHIPSENSE current sensor will solve this problem.

To do a good job, one must first have the right tools. To select the right current sensing devices for an energy storage system, it's essential to understand which sensors are needed and their functions within the system. CHIPSENSE current sensor will help you.

With the large-scale deployment of energy storage projects, Hall current sensors play a crucial role. Their applications span multiple core aspects, including battery management, system protection, energy dispatch, and power control. Their main functions are reflected in five areas: accurate current measurement, system safety assurance, efficiency optimization, fault diagnosis and early warning, and multi-scenario adaptability. These are detailed below:

1.Precise Current Measurement: The Foundation for Stable System Operation

The Hall current sensor, based on the Hall effect principle, indirectly calculates the current magnitude by measuring the magnetic field strength, enabling non-contact measurement of complex current wave-forms such as AC, DC, and pulse currents. Its high measurement accuracy, superior linearity, and long response time allow it to capture dynamic changes in current in real time. For example, during battery charging and discharging, the sensor can accurately monitor the current value, ensuring the battery pack operates within a safe current range and preventing performance degradation or damage caused by abnormal current.

2. System Safety Assurance: Constructing a Multi-Level Protection System

Overcharge and Over-Discharge Protection: By monitoring the battery charging and discharging current in real time, sensors can trigger protection mechanisms to prevent the risk of thermal runaway caused by overcharging or over-discharging. For example, when the charging current exceeds a threshold, the sensor immediately sends a signal, and the system automatically cuts off the charging circuit to ensure battery safety.

Short Circuit Fault Isolation: When a short circuit occurs in the energy storage system, sensors can quickly identify abnormal current wave-forms (such as transient peaks), working with circuit breakers to achieve millisecond-level fault isolation and prevent the accident from escalating.

Insulation Performance Monitoring: Some sensors integrate insulation resistance detection functions, which can monitor the battery pack's insulation status to ground in real time, preventing the risk of leakage caused by insulation aging.

3. Efficiency Optimization and Enhancement: Driving Refined Energy Management

Power Control Optimization: Sensors provide real-time current feedback to the power storage converter (PCS), supporting power factor correction (PFC) and efficiency optimization algorithms. For example, in an integrated photovoltaic-storage-charging system, sensors can coordinate the power allocation of photovoltaic power generation, energy storage charging and discharging, and charging piles, achieving overall system efficiency improvement.

Energy Dispatch Support: By monitoring the charging and discharging power of the battery pack, sensors provide data support to the energy management system (EMS), helping the system dynamically adjust its operating mode according to time-of-use pricing, demand response, and other strategies, reducing electricity costs.

4. Fault Diagnosis and Early Warning: Achieving Predictive Maintenance

Historical Data Analysis: Sensors record current data over a long period, and combined with artificial intelligence algorithms, can predict the state of health (SOH) and remaining battery life (RUL). For example, by analyzing current fluctuation trends, potential problems such as battery capacity decay or increased internal resistance can be detected in advance.

Anomaly Pattern Recognition: Sensors can identify seven common fault modes, such as poor contact and cable aging, and achieve local diagnosis through edge computing technology, reducing downtime. For example, an energy storage project located a contactor contact oxidation problem through sensor data, thus preventing a major failure. CHIPSENSE Current Sensor has been paying attention to this issue.

5. Multi-Scenario Application Adaptability: Meeting Diverse Needs

High-Voltage DC Scenarios: Addressing the trend towards higher voltage in energy storage systems, the sensors employ enhanced insulation design, with withstand voltage ratings ranging from 20kV to 50kV, adapting to 800V and above high-voltage platforms. For example, Huawei Digital Energy charging piles utilize fluxgate sensors to achieve ±0.5% accuracy charging control.

Extreme Environment Applications: In special scenarios such as high altitudes and tropical rainforests, sensors enhance reliability through temperature compensation and anti-mold treatment technologies. For example, an energy storage project in Tibet, operating at an altitude of 3500 meters, employed enhanced sensors to address the issue of decreased insulation performance.CHIPSENSE current sensor always provides convenience to customers.

Second-Hand Utilization Scenarios: In retired battery energy storage systems, sensors extend battery life through high-precision measurements. For example, a second-hand utilization project improved system efficiency by 1.2% and generated over 800,000 yuan in annual revenue by optimizing sensor layout.CHIPSENSE current sensors are all centered on saving costs for customers.

With the development of energy storage technology, the requirements for current sensing are becoming increasingly stringent and sophisticated. The following are the main requirements for current sensing in modern energy storage systems:

1. High Precision

Error Range: Current detection error is typically required to be within ±0.5% to ensure accurate assessment of battery state of charge (SOC) and state of health (SOH). CHIPSENSE current sensors are all products known for their excellent linearity.

Dynamic Response: Under rapidly changing load conditions (such as fast charging of electric vehicles and grid-connected energy storage systems), the sensor needs high dynamic response capabilities to avoid hysteresis or overshoot.

2. Wide Measurement Range

Current Range: The charging and discharging currents of energy storage systems can range from a few amperes to thousands of amperes. The sensor needs to cover the entire measurement range from minute leakage currents to large currents. CHIPSENSE current sensors have different measurement ranges for different applications.

Bidirectional Measurement: The sensor should be able to accurately measure current in both charging and discharging directions to support applications with bidirectional energy flow.

3. High Reliability and Stability

Environmental Adaptability: Sensor performance should not significantly degrade under extreme temperatures (-40°C to 85°C), high humidity, and strong electromagnetic interference. But CHPSENSE current sensor will do it.

Long-Term Stability: The sensor should not exhibit significant drift or aging during long-term use (e.g., over 10 years) to ensure the long-term reliability of the system.

4. Low Power Consumption and High Efficiency

Energy Loss: The sensor's power consumption should be as low as possible to avoid negatively impacting the energy efficiency of the energy storage system.

Integrated Design: Supports integration with BMS (Battery Management System) or PCS (Power Conversion System), reducing additional energy loss and space occupation.

5. Safety and Fault Diagnosis

Insulation and Isolation: Sensors require high-voltage isolation (e.g., above 3kV) to prevent high-voltage side faults from propagating to the low-voltage control system.

Fault Detection: Capable of real-time detection of faults such as short circuits, overcurrent, and leakage, and triggering protection mechanisms (e.g., relay disconnection, alarm activation).

Data Integrity: Supports self-testing and calibration functions to ensure data accuracy and reliability.

6. Intelligence and Communication Capabilities

Digital Output: CHIPSENSE current sensor supports digital communication interfaces such as CAN, Modbus, and I2C for real-time interaction with host computers or cloud platforms.

Edge Computing: Some high-end sensors support local data processing, such as filtering and fault prediction, reducing the burden on the main control system.

7. Cost and Maintainability

Economy: The cost of the sensor should be commensurate with the overall cost of the energy storage system while meeting performance requirements.

Ease of Installation and Maintenance: Supports modular design for easy on-site installation, replacement, and maintenance. The installation of the CHIPSENSE current sensor is very convenient.

8. Standards and Certifications

Industry Standards: Complies with relevant energy storage system standards such as IEC 62619, UL 1973, and GB/T 36276. CHIPSENSE current sensors all comply with national standards.

Safety Certifications: Certified by CE, UL, CSA, etc., ensuring product safety and compliance. CHIPSENSE current sensor do well in these aspects.

For high-precision and high-reliability requirements, Hall effect sensors (such as closed-loop Hall sensors) and fluxgate sensors are the mainstream choices. Especially CHIPSENSE current sensors.

For cost-sensitive applications, shunts or open-loop Hall sensors can be used as alternatives, but a trade-off between accuracy and stability is necessary. CHIPSENSE current sensor has strict requirements in this regard and has achieved significant results.

CHIPSENSE CR1A H00 is a closed-loop (compensated) current sensor based on the Hall principle, used to measure DC, AC, and pulse currents. It features:

Insulation between primary and secondary sides

Raw materials conform to UL 94-V0

High accuracy (±0.5% @ IPN), low linearity error (±0.1%), suitable for energy storage applications requiring precise current data.

Low temperature drift: ±0.2mA (typical) and gain error ±0.2%

No insertion loss

Complies with standards: IEC60664-1:2020, IEC61800-5-1:2022, IEC62109-1:2010, suitable for high-voltage, high-safety energy storage systems.

Operating temperature: -40~85℃

Insulation withstand voltage up to 3kV, impulse withstand voltage 5.4kV, meeting the insulation and over-voltage protection requirements of energy storage systems.

Clearance:10.2 mm; Creepage distance: 15.0 mm. Suitable for 600 V reinforced insulation or 1000V basic insulation scenarios, meeting the electrical safety requirements of energy storage systems.

Product series:Covering rated currents from ±50A to ±300A, with a measurement range expandable to ±70A to ±500A, meeting the current monitoring needs of battery management, inverters, converters, and other components in energy storage systems.

Fast response time (≤1μs, typically 0.5μs) and 200 kHz bandwidth:Suitable for monitoring rapidly changing currents in energy storage systems, such as PWM control and fault detection.

In electrochemical energy storage systems, CHIPSENSE CR1A H00 series Hall current sensors can be specifically applied to the following key components and stages, playing a role in current monitoring, protection, and control:

1 Battery Management System (BMS)

Application Components:

Charging and discharging circuits of battery modules/cells

Main positive and negative terminals of the battery pack

Functions:

Real-time monitoring of the charging and discharging current of each battery module or battery pack to prevent overcharging/over-discharging.

Calculation of the battery's state of charge (SOC) and state of health (SOH) to improve battery life and system safety.

Detection of short circuits or abnormal currents, triggering protection mechanisms (such as disconnecting relays).

Selection Recommendations:

Select a sensor with a range appropriate to the battery pack's maximum operating current (e.g., CHIPSENSE CR1A 200 H00 current sensor is suitable for ±200 A current).

2. Power Conversion System (PCS)

Application Components:

DC Bus: The bus connecting the battery and the inverter.

AC Side: The output connecting the grid or load.

IGBT Arms: Used to monitor the current in each phase, enabling PWM control and fault detection.

Functions:

Monitor DC bus current to prevent over-current damage to IGBTs or capacitors.

Monitor AC side current to achieve grid-connected current control, power factor correction (PFC), and harmonic suppression.

Detect IGBT arm current to achieve over-current protection and fault location.

Selection Recommendations:

DC Side: Select a high-range sensor (e.g., CR1A 300 H00, suitable for ±300 A).

AC Side: Select the appropriate range based on the inverter power (e.g., CR1A 100 H00, suitable for ±100 A).

3. DC Distribution Unit

Application Components:

DC Bus: The bus connecting multiple battery clusters or converters.

DC Circuit Breaker/Fuse: Used for over-current protection.

Functions:

Monitor bus current, balance the load of each branch, and prevent bus overload.

Provide over-current trigger signals for circuit breakers, enabling rapid protection.

Selection Recommendations:

Select the sensor range based on the maximum bus current (e.g.,CHIPSENSE CR1A 200 H00 current sensor).

4. Insulation Monitoring Device (IMD)

Application Components:

System-to-ground insulation detection circuit

Function:

In conjunction with the insulation monitoring device, detect the insulation resistance to ground of the energy storage system to prevent leakage and insulation faults.

Monitor the insulation status of the DC system, CHIPSENSE current sensor conforming to IEC61800-5-1 and IEC62109-1 standards.

Selection Recommendations:

Select a sensor with high insulation withstand voltage (e.g., CHIPSENSE CR1A series current sensor, insulation withstand voltage 3kV).

5. Testing and Diagnostic Equipment

Application Components:

System Integration Test Bench: Used for factory testing of energy storage systems.

Fault Diagnostic Instrument: Used for on-site maintenance and troubleshooting.

Functions:

Accurately measures current wave-forms to verify system performance (e.g., efficiency, response time).

Diagnoses abnormal currents in batteries, converters, or buses.

Selection Recommendations:

Select high-precision, wide-bandwidth sensors (e.g., CHIPSENSE CR1A 50 H00 current sensor, 200 kHz bandwidth) according to testing requirements.

6. Other Auxiliary Components

Pre-charge circuit: Monitors the pre-charge current to prevent capacitor damage from surges.

Air-cooled/liquid-cooled system: Monitors the drive current of the cooling system to ensure proper heat dissipation.

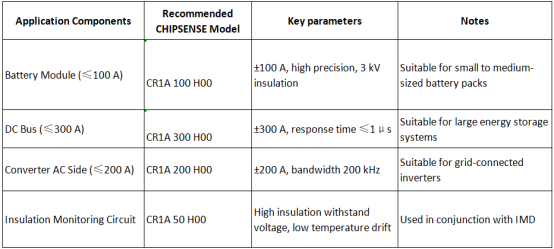

Selection Table

In summary, CHIPSENSE CR1A H00 series current sensor can be widely used in core components of energy storage systems, such as battery management, inverters, DC power distribution, insulation monitoring, and testing and diagnostics. Through precise current monitoring, it improves the safety, reliability, and efficiency of the system. When selecting a model, the appropriate type should be matched based on the current range, installation space, and insulation requirements of the specific component. CHIPSENSE also has staffs to assist with the selection of models and to customize current sensors specifically for each customer.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806