In modern industry, new energy, AIDC power systems, and rail transportation, accurate current measurement is crucial for system safety, energy efficiency management, and equipment protection. Especially in high-power applications, achieving stable and isolated measurement of currents ranging from hundreds to thousands of amperes has been a key focus in the technology field. CHIPSENSE is also paying attention to this issue.

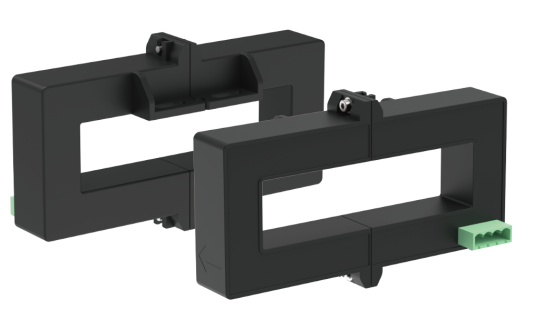

Traditional contact-type current sensors (such as shunts) suffer from problems such as difficult insulation, slow response, and complex installation. Hall effect current sensors, as a non-contact measurement solution, have seen continuous improvements in performance and applicability in recent years. While closed-loop Hall effect sensors offer excellent performance, their high cost and large size make them unsuitable for all application scenarios. Recently, CHIPSENSE launched the HK4V H00 series open-loop Hall effect current sensors, which offer a new solution for high-current monitoring in industrial applications due to their high insulation, fast response, and wide measurement range.

Technical Principle of Open-Loop Hall Sensors

Open-loop Hall sensors are based on the Hall effect, indirectly calculating current by measuring changes in the magnetic field around a conductor. Compared to closed-loop Hall sensors, they have a simpler structure and lower cost, but their accuracy and linearity are easily affected by temperature and external magnetic fields. CHIPSENSE HK4V H00 series current sensor optimizes performance through the following technical means:

Comparison of Core Technical Parameters The table below compares the key parameters of CHIPSENSE HK4V H00 series current sensor with those of common open-loop Hall sensors on the market:

Parameter Comparison of the HK4V H00 Series Current Sensor from CHIPSENSE with Open-Loop Hall Sensors on the Market

| Parameter Items | CHIPSENSE HK4V H00 series | Mainstream products on the market |

| Measurement Range | 800A–5000A | usually≤3000A |

| Response Time | <3μs | 5–10μs |

| Linearity Error | ≤±0.5% | ≤±1% |

| Insulation Withstand Voltage | 3.6kV/6.6kV | 2–3kV |

| Operating Temperature | -40°C to 85°C | -20°C to 70°C |

CHIPSENSE current sensor Key Advantages:

Precise Measurement: Utilizes a stable Hall effect principle and precision circuit design to ensure high-precision measurement data.

Safe and Reliable: CHIPSENSE current sensors are high insulation between the primary and secondary sides meets international safety standards, ensuring the safety of operators and equipment.

Strong Environmental Adaptability: Wide operating and storage temperature range ensures stable operation of the product in various harsh environments.

Easy Integration: Open mounting holes and connector design simplify the installation process and improve work efficiency.

CHIPSENSE Current Sensors Technical Highlights:

Open-loop Hall effect technology: Based on the Hall effect principle, enabling non-contact current measurement.

Wide bandwidth response: Bandwidth reaches DC~40kHz, meeting the needs of high-frequency current measurement.

High insulation withstand voltage: AC isolation withstand voltage test effective value up to 3.6kV, CHIPSNESE current sensors are must ensure safe use.

Low zero-point temperature drift: Zero-point temperature drift controlled within ±0.5mV/℃, ensuring measurement stability.

Fast response: Response time as short as <3μs (typical value), capturing instantaneous current changes.

Wide measurement range: CHIPSENSE current sensors Covering 800A to 5000A primary-side rated current, meeting the needs of different scenarios.

Stable linearity: Linearity error ≤±0.5%, ensuring accurate and reliable data.

Application Scenarios and Solutions

1. New Energy Power Generation and Energy Storage

Problems:

The AC side of the photovoltaic inverter and the DC bus of the energy storage system require real-time monitoring of high current to assess system efficiency, fault diagnosis, and safety protection;

Traditional shunts or closed-loop Hall sensors are costly or complex to install (requiring power disconnection and wire disconnection) in high-voltage, high-current scenarios.

Solutions:

AC Current Monitoring: CHIPSENSE HK4V H00 series current sensors can be used for AC current monitoring at the inverter output, supporting a wide bandwidth from DC to 40kHz, suitable for high-frequency PWM wave-forms;

DC Bus Monitoring: In energy storage systems, it is used to monitor the charging and discharging current of battery packs. Its high insulation (3.6kV) and fast response (<3μs) ensure data accuracy;

System Integration: The open design facilitates installation on busbars or cables without disconnecting the circuit, reducing construction risks.

Note:

MPPT controllers typically use high-precision, low-current sensors (such as closed-loop Hall effect sensors or shunts), while CHIPSENSE HK4V H00 series current sensor is more suitable for high-current scenarios (such as inverter outputs, energy storage buses, etc.).

2. Industrial High-Power Power Distribution

Problem: High demand for real-time busbar current monitoring; traditional shunts are complex to install and pose significant safety risks.

Solution: Open-type design, no need to disconnect the busbar, quick installation; high insulation withstand voltage (3.6kV/6.6kV) ensures operational safety, suitable for load management and overload protection in distribution cabinets.

3.AI Data Center Power Supply (AIDC Power System)

Problem: AI servers and high-performance computing devices have extremely high requirements for power supply stability and power density. Traditional current monitoring solutions struggle to meet the demands of high-frequency dynamic loads and rapid response.

Solution:

Fast Response: Response time <3μs enables real-time capture of current fluctuations, ensuring precise control of the UPS and Battery Management System (BMS);

High Precision and Low Temperature Drift: Linearity error ≤±0.5%, zero-point temperature drift ±0.5mV/℃, providing reliable data for current sharing and overcurrent protection of power modules;

Modular Integration: Standardized mounting holes and connectors facilitate integration into rack-mounted power systems, improving deployment efficiency.

4. Electric Propulsion for Rail Transit

Problem: Traction inverters require real-time current feedback;Current sensors must be resistant to high temperatures and vibration.

Solution: Wide operating temperature range of -40°C to 85°C; robust mechanical structure; adaptable to the harsh operating environments of trains and ships. CHIPSENSE current sensor is a good choice.

5.Large-Scale Specialized Power Supplies: Achieving closed-loop current control in equipment such as electroplating and electrolysis contributes to improved process stability.

Selection Recommendations and Precautions

Selection Guide: Select the appropriate model based on the actual current range:

800A–1500A: CHIPSNESE HK4V 800/1000/1500 H00 current sensor;

2000A–5000A: CHIPSENSE HK4V 2000/3000/5000 H00 current sensor.

Safety Instructions:

CHIPSENSE current sensors install according to IEC61800-5-1 standard;

Ensure that the conductive parts of the sensor are not exposed; install a protective cover if necessary;

The main power supply should have an emergency disconnect function.

Risk Warnings and Technical Limitations

Temperature Influence: Although the low-temperature drift design is optimized, calibration is still required under extreme temperatures;

External Magnetic Field Interference: Open-loop Hall sensors are sensitive to external magnetic fields and should be installed away from strong magnetic sources;

Accuracy and Cost Balance: Compared to closed-loop sensors, the accuracy is slightly lower, but the cost-effectiveness is higher, making it suitable for most industrial scenarios.

Conclusion: Balancing Technology and Application

CHIPSENSE HK4V H00 series open-loop Hall effect current sensor, with its high insulation, fast response, and wide measurement range, provides a balanced solution for industrial high-current monitoring, offering both cost-effectiveness and performance. In fields such as new energy and rail transportation, its non-contact measurement and safety design effectively reduce maintenance risks and improve system reliability. Users should make the optimal choice based on their actual current range, environmental conditions, and accuracy requirements.

Technical Discussion: What technical challenges have you encountered in industrial current monitoring? Feel free to leave a comment and discuss.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806