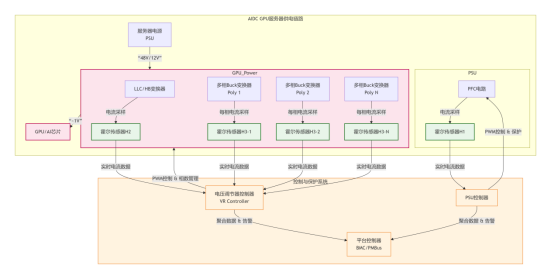

With the iterative upgrades of large-scale models such as DeepSeek, ChatGPT, and Sora, global AI computing centers are experiencing unprecedented expansion. Statistics show that the power consumption of a single large-scale model training session is equivalent to the monthly electricity consumption of tens of thousands of households, while the annual electricity consumption of AI computing centers already accounts for more than 20% of the total electricity consumption of global data centers. High-power GPU clusters, liquid-cooled servers, and other equipment place extremely high demands on the stability and energy efficiency of power supply systems: how to achieve refined energy consumption management while ensuring power supply stability? This issue has become a focus of industry attention. The article will take CHIPSENSE CM5A 2000 H01 hall closed-loop current sensor as an example.

Key Issue: How to achieve both stability and energy efficiency in power supply systems?

Stability Challenges: High instantaneous loads in AI computing centers (such as peak loads during model training) can easily lead to current fluctuations. Traditional open-loop current sensors struggle to accurately capture these transient changes, potentially causing false triggering of over-current protection or power outages.

Energy Efficiency Challenges: Inaccurate energy consumption monitoring leads to energy waste or excessive protective measures (such as redundant power supply configurations), directly impacting the Power Usage Effectiveness (PUE) metric.

Technical Bottlenecks: Most current sensors on the market lack sufficient accuracy or have slow response times under high-current conditions, failing to meet the high dynamic demands of AI computing centers.

Current Monitoring Needs of AI Computing Centers (AIDCs)

AI computing centers face the following current monitoring challenges:

High power density: GPU clusters and liquid-cooled servers can generate instantaneous power consumption of tens of kilowatts, with frequent current fluctuations.

Energy efficiency management: PUE (Power Usage Effectiveness) optimization requires accurate energy consumption data, with errors controlled within ±0.5%.

Safety and stability: Over-current protection must respond in real time to prevent equipment damage or power outages.

Problem Analysis: Pain Points in Current Monitoring for AI Computing Centers

Accuracy Attenuation: Open-loop sensors can have an error of ±3% at 1000A, which cannot meet the requirements for high-precision energy consumption monitoring.

Data Lag: Traditional sensors suffer from data acquisition lag, making real-time PUE optimization impossible and leading to energy waste.

Installation Complexity: Traditional sensors are bulky and require external power, making them unsuitable for high-density rack environments.

Technical Principle: Advantages of Hall Effect Closed-Loop Current Sensors

The Hall effect closed-loop current sensor is based on the Hall effect principle, converting current into a voltage signal through a Hall element to achieve non-contact measurement. Its core advantage lies in the closed-loop negative feedback circuit:

High Precision: Through real-time error compensation, the accuracy of ordinary closed-loop sensors reaches up to 0.3%, far exceeding the 1% of open-loop sensors. CHIPSENSE current sensors can do this.

Wide Measuring Range: Supports a large current range of 100-2000A, covering the main power supply circuit and branch circuits of AI computing centers. CHIPSENSE current sensors meet this.

Fast Response: The closed-loop structure reduces response time to the microsecond level, making it suitable for scenarios with transient load changes. CHIPSENSE current sensors have received a lot of positive feedback.

Solution Comparison: Hall Effect Closed-Loop Sensor vs. Mainstream Products on the Market

| Comparison Dimensions | Hall effect closed-loop sensor | Mainstream open-loop sensor in the market | Fluxgate sensor |

| Accuracy | 0.30% | 1% | 0.1% (but small range) |

| Measuring Range | 100-2000A | 50-800A | 10mA-300mA |

| Response Speed | Microsecond level | Millisecond level | Millisecond level |

| Applicable Scenarios | High-power main circuit | Low-to-medium power branch circuit | Leakage current monitoring |

| Ease of installation | PCB integration or modular | External power supply required | Requires dedicated installation space |

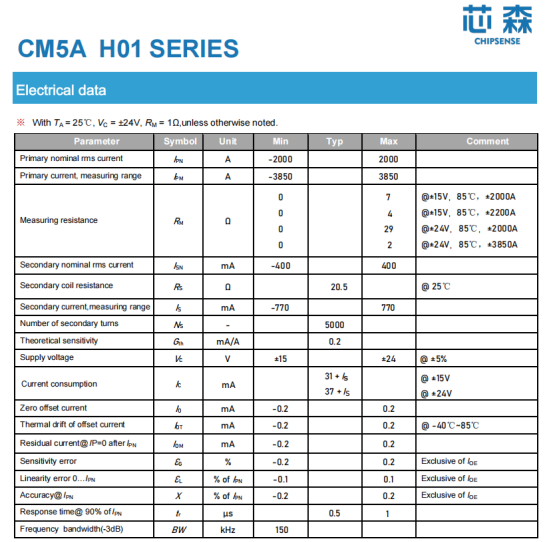

CHIPSENSE CM5A 2000 H01 current sensor is a closed-loop (compensated) current sensor based on the Hall effect principle, designed specifically for high-power, high-precision current monitoring applications. Its core features include:

High Precision: Accuracy reaches ±0.2% (typical value), far superior to ±1% of open-loop sensors.

Wide Measuring Range: CHIPSENSE current sensor Supports ±2000A steady-state current, with a maximum measurement range of ±3850A, fully covering the current requirements of the main power supply circuit of AI computing centers and high-power GPU racks.

Fast Response: CHIPSENSE CM5A 2000 H01 current sensor Response time of only 0.5μs (typical value), enabling real-time capture of transient load changes and avoiding false triggering of over-current protection.

High Reliability: Insulation withstand voltage up to 6kV (AC isolation withstand voltage test), transient withstand voltage 23kV, CHIPSENSE current sensors are meeting IEC61800-5-1 and IEC 62109-1 CAT III standards.

CHIPSENSE current sensor operating Temperature Range -40°C to 85°C, adaptable to the complex environment of data centers.

Low Temperature Drift and High Linearity: Ensures data stability during long-term operation.

CHIPSENSE CM5A 2000 H01 Current Sensor Applicability Analysis

Accuracy and Range Matching

The main power supply circuit and high-power cabinet current in AI computing centers typically range from hundreds to thousands of amperes. CHIPSENSE CM5A current sensor’s ±2000A range and 0.2% accuracy fully meet these requirements.

CHIPSENSE closed-loop design ensures high linearity even under high current conditions, avoiding the accuracy degradation issues common in open-loop sensors.

Response Speed and Stability

A 0.5μs response time enables real-time monitoring of peak GPU training current, coupled with a fast over-current protection mechanism to improve power supply stability.

A 150kHz current sensors of CHIPSENSE bandwidth supports accurate measurement of high-frequency pulse current, suitable for dynamic loads such as inverters and frequency converters.

Safety and Reliability

6kV insulation withstand voltage and 23kV transient withstand voltage meet the high-voltage safety requirements of AI computing centers.

CHIPSENSE current sensor under UL94-V0 flame-retardant materials and IP-rated design ensure long-term reliability in high-temperature and high-humidity environments.

Ease of Installation and Integration

Standardized mechanical dimensions (134mm×152mm×59mm) and M6 mounting holes facilitate integration into distribution cabinets or rack-mounted PDUs.

4-wire output (±Vcc, Vout, GND) simplifies wiring and supports analog or digital signal acquisition.

CHIPSENSE CM5A 2000 H01 Current Sensor Typical Application Scenarios

Main Power Supply Circuit Monitoring

Deployment Location: Incoming line terminal of distribution cabinet, monitoring total current fluctuations.

Results:

Real-time capture of instantaneous peak values, preventing false triggering of over-current protection.

Accurate energy consumption metering, providing data support for PUE optimization.

High-Power Rack Energy Efficiency Management

Deployment Location: PDU outgoing lines of the GPU rack.

Results:

Real-time collection of rack-level energy consumption data, combined with AI algorithms to dynamically adjust load distribution.

Reduces energy consumption errors and improves energy efficiency ratio.

Fault Warning and Safety Protection

Fault Warning and Safety Protection

Deployment Location: Critical load circuits (e.g., inverter, UPS output).

Effects:

Real-time monitoring of abnormal current, triggering warnings or power outage protection.

Reduces the risk of equipment damage and improves system availability.

Comparison and Selection Recommendations

| Comparison Dimensions | CHIPSENSE CM5A 2000 H01 current sensor | Open-loop Hall effect sensor | Fluxgate sensor |

| Accuracy | ±0.2% | ±1% | ±0.1% (small range) |

| Measuring Range | ±2000A (maximum ±3850A) | Typically ≤±800A | Typically ≤±300A |

| Response Speed | 0.5μs | Millisecond level | Millisecond level |

| Applicable Scenarios | High-power main circuit | Small to medium power branch circuit | Leakage current/tiny signal |

| Safety Level | 6kV insulation/23kV transient withstand voltage | Typically ≤3kV | Typically ≤1kV |

| Ease of installation | Standardized mechanical dimensions / M6 installation | External power supply required | Dedicated installation space required |

Selection Recommendations:

For the main power supply circuit and high-power cabinets of AI computing centers, CHIPSENSE CM5A 2000 H01 current sensor is the preferred choice, as its high precision, wide measurement range, and fast response can maximize the fulfillment of requirements.

For branch circuit or leakage current monitoring, it can be used in conjunction with CHIPSENSE open-loop or fluxgate sensors.

Risk Warnings and Precautions

Safety Risks:

Power must be disconnected during installation to avoid electric shock or damage to the sensor.

Ensure the primary busbar temperature does not exceed 100°C to prevent degradation of insulation performance.

Environmental Adaptability:

Avoid strong magnetic field interference, which may affect measurement accuracy.

Regular calibration is necessary to ensure long-term data accuracy.

Cost and ROI:

Closed-loop sensors are more expensive than open-loop products, but their high accuracy and reliability significantly reduce energy consumption and maintenance costs, resulting in a significant long-term ROI.

Conclusion

CHIPSENSE CM5A 2000 H01 hall-effect closed-loop current sensor, with its high accuracy, wide measurement range, fast response, and high reliability, is an ideal choice for power supply systems in AI computing centers. Whether it's monitoring the stability of the main power supply circuit or managing rack-level energy efficiency, CHIPSENSE CM5A current sensor provides a "stable yet energy-saving" solution, helping to achieve green and efficient AI computing infrastructure.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806