Foreword:

The current leakage current detection is to detect the leakage current of the power transmission cable, that is, to penetrate two power transmission cables into the magnetic ring at the same time. If no leakage current occurs, the leakage sensor output is zero.

However, this method cannot detect the leakage of the metal part of the solar panel. This paper proposes an idea to solve this problem, which can solve the solar metal leakage phenomenon.

As mentioned above, the goal of GFDI is not to protect human safety, but only to ensure the safety, durability and reliability of equipment operation. There is a safety issue here, how to protect human life. In other words, in the premise of ensuring the safety of life, we should also ensure the safety of equipment.

The current common practice is to detect leakage current: when a human body accidentally touches the metal part of the power transmission cable and causes an accidental electric shock, the current will flow through the human body to the ground, and this current is a leakage current. After this leakage current is detected by the sensor, the program automatically controls to immediately disconnect the device/or alarm output; but this has omissions, namely: the safety accident caused by the leakage of the metal frame of the solar panel cannot be detected;

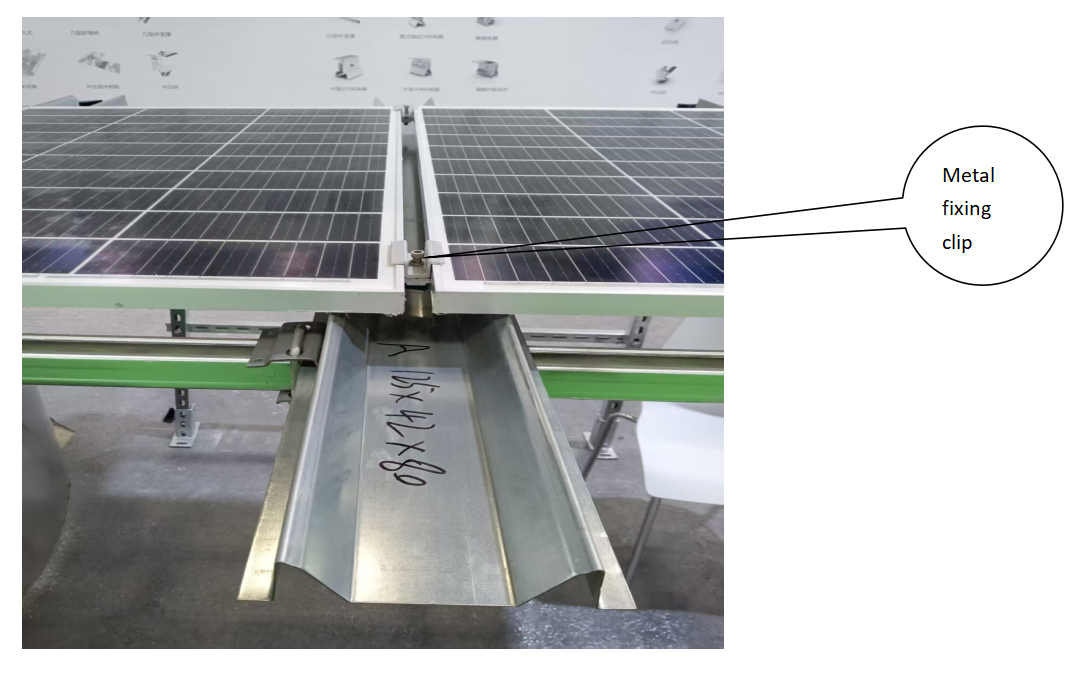

Whether it is a string type or a centralized type, multiple solar panels are strung and connected together to finally form a high-voltage 1500V/2000V system. The metal shell of each minimum unit solar panel is fixed together through a metal fixing clip, as shown below:

The high-voltage PV power supply is the smallest unit of solar panels, which are fixed in a similar way to side by side. Then as long as there is a leakage in one place, the entire outer frame will be fully charged. CHIPSENSE products will take this into account.

As mentioned before, for the reliable and durable operation of the equipment, only the negative electrode of the power transmission cable can be grounded. Therefore, the metal shell is not detected and protected.

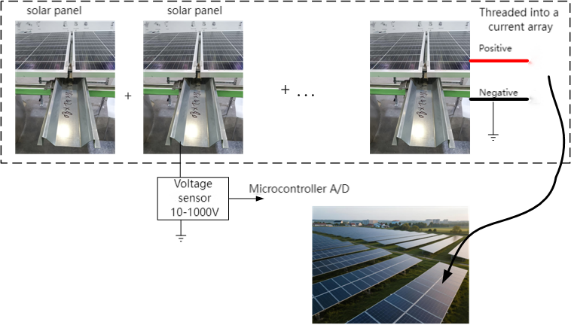

CHIPSENSE now propose a new method to add a voltage detection device on the basis of the above-mentioned GFDI to detect the voltage of the metal shell of the solar panel to the ground in real time, so that the GFDI/GFCI can be satisfied at the same time. As follows principle diagram:

Between the metal shell of the high-voltage PV power supply and the ground, a voltage sensor for detection is connected to monitor the voltage in real time. Once the metal shell is charged due to the destruction of the PV insulation layer, it will be detected. The program controls as long as the safe voltage is higher than 36V, outputs sound and light alarms, and transmits the alarm information to the remote background through PSTN/WIFI and other means, thus forming a complete application system. CHIPSENSE voltage and current sensors are all based on this principle.

1.The device can consider CHIPSENSE VN2A P00 voltage sensor, or even CHIPSENSE VN1V -1M-P01. The appearance of VN2A voltage sensor from CHIPSENSE is as follows

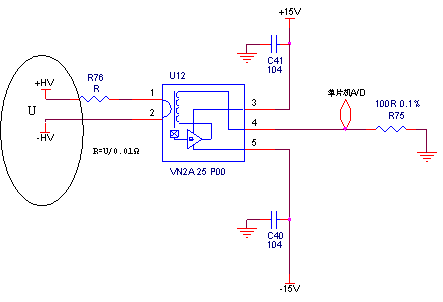

2. Introduction and application circuit diagram of CHIPSENSE VN2A P00 voltage sensor

The rated measurement voltage range of CHIPSENSE VN2A P00 voltage sensor is 10V-1500V, the maximum measurement voltage is 1800V, and the insulation withstand voltage value of the device is 4.2kV, which can be reliably applied to 1500V PV power supplies. So CHIPSENSE voltage sensor is a good choice.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806