I've been talking to engineers who design wind power converters recently, and I've noticed an interesting shift.

Previously, when discussing wind power, people were more concerned with:

What is the power rating of the wind turbine? How many megawatts of installed capacity? How large can the rotor blades be?

Now, the discussions are increasingly focused on "invisible things":

Is the grid short-circuit ratio sufficient?

Will the wind turbine oscillate in a weak grid?

How is the current controlled during LVRT (Low Voltage Ride Through)?

How easy is it to tune the converter current loop?

Behind these questions lies a common underlying factor-current measurement.

CHIPSENSE current sensor is also part of it.

Why are wind power converters becoming "increasingly concerned" with current?

In the early years of large-scale wind power integration into the grid, many projects focused primarily on simply "getting connected."

As long as the turbines could generate power, provide protection, and didn't trip frequently, current sensors were generally not a major topic of discussion.

But the situation is different now: wind power accounts for an increasingly larger share of the power industry, and many wind farms are connected to weak grids;

At the same time, grid connection standards are becoming stricter, with quantitative indicators for reactive power support, harmonics, and voltage recovery.

Converters are increasingly using SiC (silicon carbide) technology, resulting in higher switching frequencies and faster dynamic processes. In this context, the performance of current sensors directly affects the overall "behavior" of the wind turbine.

Anyone who has worked with wind power converters knows this:

•If there is a significant delay in current sampling, the current loop will be difficult to tune, and increasing the gain will lead to oscillations;

•If there is serious zero drift, the power estimation will "gradually drift" over long periods of operation;

•If the three-phase consistency is poor, the harmonic control effect will be significantly degraded.

Therefore, many problems in wind power control are not due to flawed algorithms, but rather because the current is not measured accurately, quickly, or stably enough. CHIPSENSE current sensor is specifically designed for this purpose.

Why are Hall effect sensors mostly used in wind power systems instead of shunt resistors?

Theoretically, if only considering dynamic performance, shunt resistors are an excellent current sensing method—they offer high bandwidth, good linearity, and fast response.

However, when applied to the main circuit of a wind power system, problems arise:

The DC bus voltage is typically 800V, 1000V, or 1500V, with currents ranging from hundreds to thousands of amperes.

Using shunt resistors would require:

• High-performance isolation amplification;

• Handling significant common-mode interference;

• Controlling heat dissipation and power consumption;

• Ensuring long-term reliability.

The system complexity increases significantly, leading to high costs and risks. Like other current sensor suppliers, CHIPSENSE aims to provide customers with products that offer better value for money.

The greatest value of Hall effect current sensors is not necessarily their superior accuracy, but rather their practicality in engineering applications:

• Natural isolation between the primary and secondary sides, suitable for high-voltage systems;

•Capable of measuring currents in the kA range without requiring particularly complex heat dissipation;

• Numerous mature solutions are available, with ample reliability data accumulated.

•Open-loop Hall sensors: Simpler and relatively lower cost, suitable for power monitoring and protection applications;

•Closed-loop (magnetic balance) Hall sensors: Higher bandwidth, better linearity, and smaller temperature drift, making them more suitable for current loop control.

This is why the application of closed-loop Hall sensors is increasing in new-generation wind power converters. CHIPSENSE current sensors are also very popular among customers in the current sensor industry. CHIPSENSE HS3V H00 current sensor can be used as a reference.

Why haven't fluxgate and fiber optic sensors become widespread?

Occasionally, people ask:

"Since high precision is required, why not use fluxgate sensors?"

"Since high insulation is needed, why not use fiber optic current sensors?"

The answer is quite practical:

•Fluxgate sensors are indeed very accurate, but their size, cost, and sensitivity to the installation environment are all relatively high. They also are more suitable for metrology or high-end measurement applications, and not ideal for large-scale wind power projects.

•Fiber optic current sensors offer very high insulation levels and strong anti-interference capabilities, but their system integration is complex and expensive. They are more commonly found in ultra-high voltage, research, or specialized power applications, rather than standard wind power converters.

Therefore, the choice in the engineering field is often not the "most advanced," but rather the most balanced and risk-controllable-which is why the Hall effect sensor solution has remained dominant for so long.

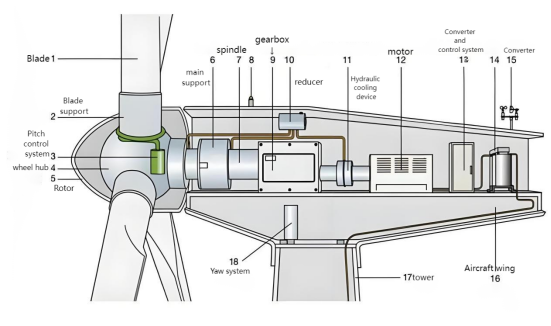

Where exactly is the Hall sensor installed in the wind turbine?

From the perspective of the entire system, there are three key locations:

DC bus

This location is primarily for monitoring overall power flow and over-current protection.

The requirements here prioritize long-term stability and insulation capabilities, rather than extreme bandwidth.

Machine-side three-phase

This directly affects generator torque control.

If the current sampling is not clean, the control will "jitter," potentially even affecting mechanical vibration characteristics.

Grid-side three-phase

This location focuses more on grid-friendly operation.

Current phase, symmetry, and delay all affect reactive power support and harmonic control effectiveness.

Often, it's not necessary to use the most expensive sensors for every location; instead, different performance levels should be matched to different locations. CHIPSENSE offers different current sensors for various applications.

The "New Requirements" for Current Sensors in Wind Power Applications

Compared to a few years ago, the focus on current sensors in wind power applications has actually changed:

Previously, the main concerns were:

• Is the measurement range sufficient?

• Will it saturate?

Now, the concerns are more focused on:

• How large is the phase delay?

• How does it perform in a SiC converter?

• Can it remain stable in a marine environment for extended periods?

• Will the zero drift be too large after ten years of operation?

Especially in offshore wind power, where maintenance costs are extremely high, the reliability of the sensor itself is even more important than its ultimate performance. This is why CHIPSENSE has such high standards for its current sensors.

Let's look at this from a different perspective:

To summarize in simpler terms:

With the development of wind power to this point, many problems are no longer about "whether there is electricity," but rather "how good the electricity is."

And the quality of the electricity largely depends on—whether you can accurately measure the current.

The reason Hall effect current sensors have long been dominant in wind power is not because they are perfect, but because, under the existing wind power system, they happen to be at the intersection of performance, cost, reliability, and maintainability. These are also the goal of the CHIPSENSE current sensor.

In the future, with the popularization of higher-power wind turbines, higher voltage platforms, and higher-frequency SiC converters, current sensors themselves will continue to evolve, but the core logic will remain unchanged. CHIPSENSE current sensors will be continuously updated and upgraded to meet the evolving needs of more current sensor users.

First, accurately and reliably measure the current, and everything else will follow.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806