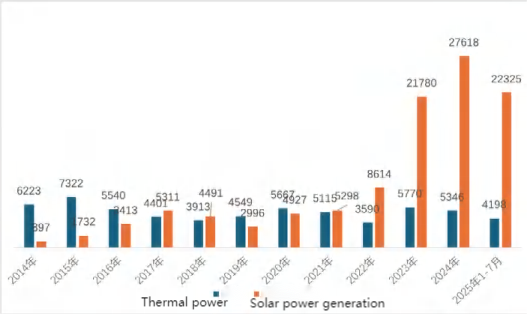

From January to July 2025, China's installed photovoltaic (PV) capacity increased by 223 million kilowatts, bringing the total capacity to over 1 billion kilowatts, reaching 1.11 billion kilowatts, equivalent to the total installed capacity of 49 Three Gorges Dams. Western my country, with its vast land and sparse population, boasts excellent sunlight conditions, making it ideal for developing centralized PV power plants. In these plants, high-power inverters need to withstand currents exceeding 1000A, and traditional current transformers, with their low accuracy, cannot meet these requirements. This article introduces a high-power current sensor solution. CHIPSENSE current sensor will be a good example for reference.

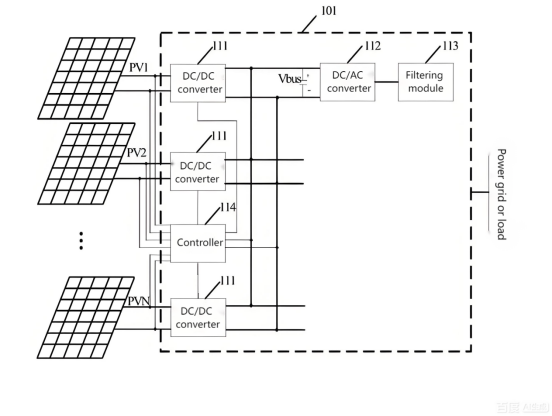

High-power photovoltaic (PV) inverters generally refer to inverters with a power output of 100kW or more. They are the core equipment of PV power generation systems, primarily used to convert the direct current (DC) generated by solar panels into alternating current (AC) for grid connection or power supply to loads. Based on power and application scenarios, they are mainly divided into two categories:

Centralized Inverters: Power range 500kW–3MW, suitable for large ground-mounted power plants, commercial and industrial rooftops, etc., offering high output power and simple operation and maintenance.

String Inverters: Power range 20kW–400kW, offering high flexibility and adaptability to complex terrain.

High Accuracy:

A 0.1% increase in inverter efficiency can increase annual power generation by 0.5%–1% (for a 1MW system, this translates to an annual revenue increase of approximately ¥3,000–6,000).

Current sensing error must be controlled within ±0.5% to ensure the accuracy of the MPPT (Maximum Power Point Tracking) algorithm. CHIPSENSE current sensors can do it.

Wide Range:

High-power inverters have a large range of start-up/full-load current variations (e.g., 10A–2000A), requiring a wide dynamic range for the sensor. And CHIPSENSE current sensors have all kinds of dynamic range for customers.

Insulation and Safety:

For 1500V systems, leakage current detection must meet IEC62109 standard (leakage current ≤30mA).

Insulation fault risk you are concerned about: Leakage on the high-voltage DC side may lead to system shutdown or fire.

Response Speed:

Short-circuit protection must have a microsecond-level response, requiring a sensor bandwidth of 100kHz or higher.

Environmental Adaptability:

Outdoor operating temperature range -40℃~85℃, humidity 95%RH, the sensor must have high reliability. CHIPSENSE current sensors also like this.

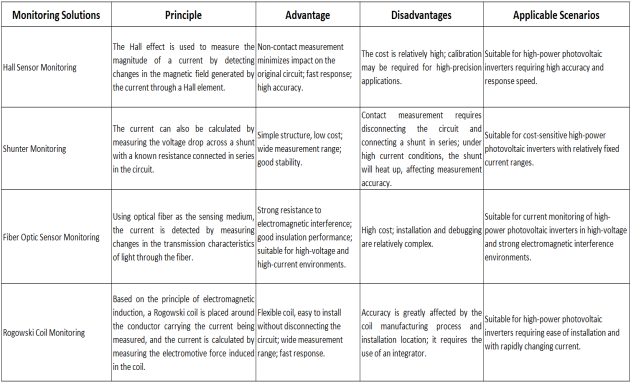

Comparison of Technical Solutions

The following table is a comparative analysis of current monitoring solutions for high-power photovoltaic inverters, covering several common monitoring methods and their advantages and disadvantages:

When selecting a current monitoring solution for a high-power photovoltaic inverter, factors such as accuracy, cost, ease of installation, and anti-interference capability need to be considered comprehensively, and the most suitable solution should be selected based on the specific application scenario and requirements. Some CHIPSENSE current sensors are recommended.

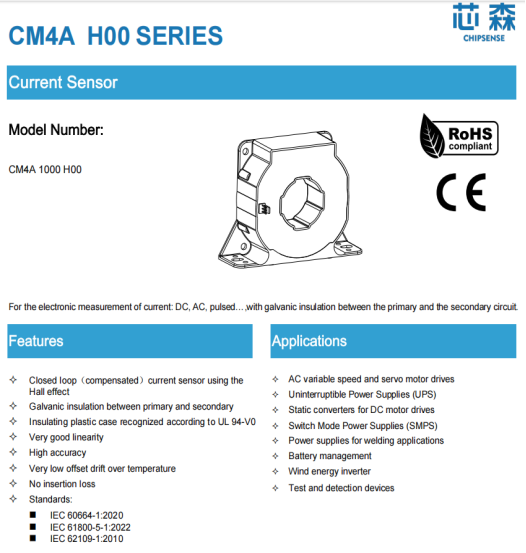

Based on the closed-loop Hall effect principle, CHIPSENSE CM4A current sensor generates a compensating current through a secondary coil to cancel the primary magnetic field, achieving zero flux detection. It features:

High accuracy: ±0.3% accuracy, ±0.1% linearity, contributing 1%–3% to MPPT efficiency improvement. CHIPSENSE current sensors have very strict accuracy requirements.

High current measurement: Measurement range ±2100A, covering systems with a current rating of 1000A+.

Strong insulation: Withstand voltage 3.8kV, creepage distance 20.6mm, CHIPSENSE CM4A current sensor compliant with IEC62109-1 standard.

Fast response: 0.5μs response time, 150kHz bandwidth, CHIPSENSE current sensors must capture transient current changes.

Application Scenarios of CHIPSENSE CM4A current sensor in Photovoltaic Inverters

1. String Inverters (20~100kW)

Requirements:

Monitor DC-side input current (CHIPSENSE CM4A current sensor 500–1000A) to ensure the accuracy of the MPPT algorithm.

Handle transient current fluctuations caused by changes in sunlight.

CHIPSENSE CM4A current sensor Solution

Accuracy ±0.3%: CHIPSENSE current sensors avoids power generation loss caused by MPPT errors.

Response Time 0.5μs: Captures transient changes such as cloud cover.

Installation Recommendations:

Vertical installation, with the busbar passing horizontally through the via (39.3×13.5mm).

Provide sufficient space for heat dissipation to prevent long-term high temperatures (>85°C) from affecting lifespan.

Example: A certain Hua inverter using CM4A current sensor from CHIPSENSE achieved a 1.5% improvement in MPPT efficiency.

2. Centralized Inverter (500kW and above)

Requirements:

Multiple sensors connected in parallel to monitor 4000A+ current to ensure system stability. Other CHIPSENSE current sensors are also good choices.

Meet the insulation requirements of a 1500V system.

CHIPSENSE CM4A Current Sensor Solution:

Multiple sensors in parallel: Even current distribution ensures measurement accuracy.

Insulation withstand voltage 3.8kV: Meets the safety requirements of a 1500V system.

Challenges:

Customized busbars are required to ensure compatibility with via dimensions.

Copper busbars are recommended to reduce contact resistance.

Case Study: A 1MW photovoltaic power station used four CHIPSENSE CM4A current sensors inverters in parallel, reducing the failure rate by 80%.

How to select a current sensor

| Application Scenarios | Recommended CHIPSENSE Models | Measurement range (A) | Accuracy | Insulation withstand voltage (kV) |

| String Inverters | CM4A H00 | ±2100 | ±0.3% | 3.8 |

| Centralized Inverters | CM4A H00(Parallel) | 4000+ | ±0.3% | 3.8 |

| Photovoltaic + Energy Storage Systems | CM4A H00 | ±2100 | ±0.3% | 3.8 |

| Micro Inverters | AN1V | ±100 | ±0.5% | 2.5 |

Case Study: Northwest 50MW Photovoltaic Power Plant

Problem: High failure rate and unstable accuracy of imported sensors.

Solution: Replace with CM4A current sensor of CHIPSENSE, improving accuracy to ±0.3% and reducing the failure rate by 30%.

Risk Warnings and Future Trends

1. Risk Warnings

Installation Incorrectness: Busbar size mismatch can lead to decreased accuracy.

Insufficient Heat Dissipation: Prolonged high temperatures can shorten sensor lifespan.

Competitive Product Alternatives: Smaller sensors (such as CHIPSENSE AN1V current sensor) are more advantageous in micro-inverters.

2. Future Trends

Miniaturization: Chip-level sensors (such as CHIPSENSE ASIC solutions) will become the trend.

Higher Integration: Sensor modules with built-in digital filtering and communication interfaces.

Higher Voltage: Increased demand for sensors adaptable to 1500V+ systems.

Conclusion

CHIPSENSE CM4A Hall-effect closed-loop current sensor, with its high precision, high current capacity, strong insulation, and fast response, has become the preferred solution for photovoltaic inverters, acting as their current sentinel. In 1000A+ systems, CHIPSENSE CM4A current sensor can provide precise protection, improve power generation efficiency, and reduce failure rates. Meanwhile, CHIPSENSE current sensor has received unanimous praise from customers.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806