With the popularity of electric vehicles, the demand for charging facilities continues to grow. During the "14th Five-Year Plan" period, our country has built the world's largest electric vehicle charging network, with 2 charging piles for every 5 electric vehicles. In order to ensure the stability and reliability of the charging process, higher requirements are placed on the performance of the core components of the charging equipment. Over-current monitoring is a key link to ensure the stable operation of the equipment, and the accuracy, response speed and reliability of its solution are crucial. AN3V series Hall current sensors launched by CHIPSENSE provide a high-precision and fast-response current monitoring solution for charging piles.

1. Current monitoring requirements during charging pile operation

The core function of the charging pile is to efficiently and stably deliver power from the grid to the vehicle battery. According to different charging methods, it is mainly divided into two categories:

AC slow charge (AC): 220V household voltage is used to convert electrical energy through the on-board charger (OBC). The charging process usually includes stages such as low voltage test, constant current, and constant voltage, which require smooth current control.

DC fast charging (DC): direct output of high voltage DC, charging pile built-in power conversion module. The vehicle identity needs to be verified through a strict handshake protocol, and the battery status (voltage, temperature, etc.) is continuously monitored, which requires extremely high real-time and accurate current changes.

During the charging process, the stability of the current is the basis for ensuring the normal operation of the equipment. To ensure the reliability of the equipment operation, the monitoring system needs to be able to identify abnormal current changes in time (such as unexpected current fluctuations due to line aging, contact problems or external disturbances) and take corresponding measures. So CHIPSENSE current sensor just made a corresponding improvement for this point.

2. Requirements for current monitoring schemes for charging piles

The ideal current monitoring solution requires the following conditions:

High accuracy: capable of accurately capturing tiny current changes.

Fast response: with extremely short signal processing delays.

High reliability: stable operation in the complex environments (such as temperature, humidity, electromagnetic interference).

Miniaturization and integration: Adapt to the compact space layout inside the charging pile.

High insulation: meets electrical safety isolation standards in high voltage environments.

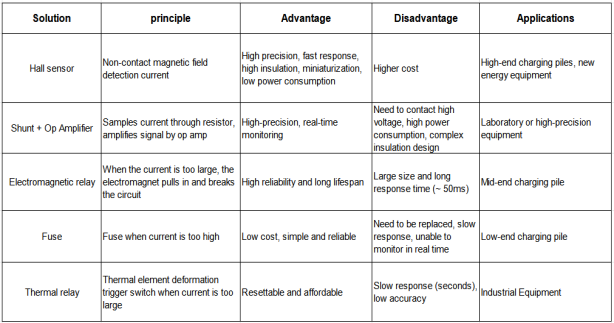

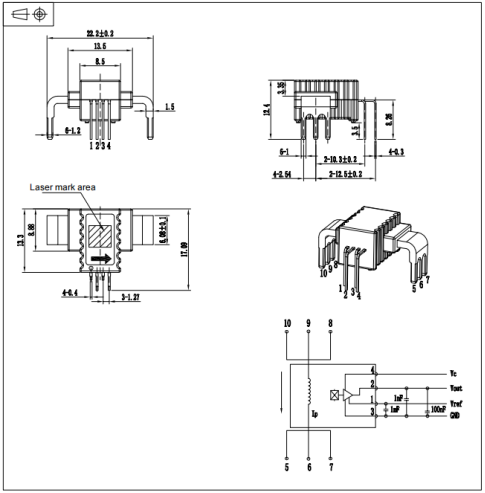

3. Comparison of mainstream current monitoring schemes

Charging piles often use a variety of current monitoring schemes, each with its own characteristics.

Performance advantages of CHIPSENSE AN3V Hall effect current sensors

CHIPSENSE AN3V Hall current sensor performs well in key performance indicators:

Comparative analysis

Fuses and thermal relays have long response times and cannot be monitored in real time, making it difficult to meet the needs of high-power, high-dynamic charging piles.

The electromagnetic relay has high reliability, but its volume and response time are the limiting factors for its application in compact charging piles.

The shunt + op amp scheme has high precision, but the power consumption, heat generation and complex insulation design caused by high voltage contact increase the system complexity and latent risk.

With its non-contact measurement, microsecond response, excellent insulation performance, low power consumption, and miniaturization, CHIPSENSE AN3V hall effect current sensor is an ideal technical solution for high-end charging piles to achieve high-precision, fast current monitoring and protection.

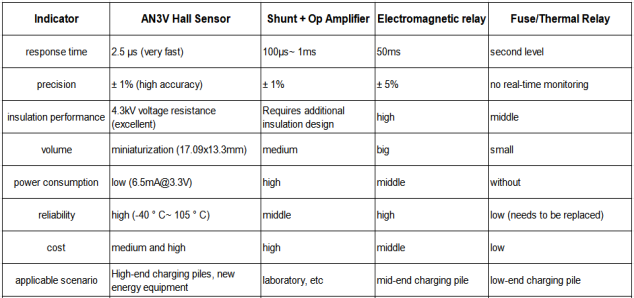

4.Application of CHIPSENSE AN3V current sensor in charging piles

Install and deploy

CHIPSENSE AN3V current sensor is directly installed on the PCB main board of the charging pile:

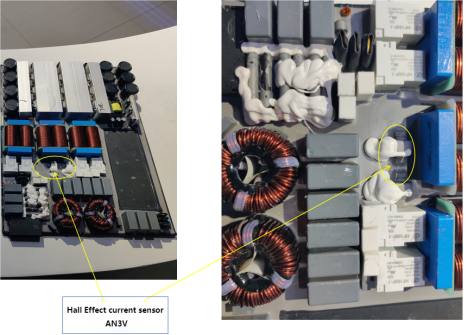

1. The primary pins (5, 6, 7) are connected in series to the main circuit that needs to monitor the current (e.g. connecting the bus or wide copper foil traces).

2. The secondary pins (1, 2, 3, 4) are connected to the main control MCU (microcontroller unit).

3. Ensure that the current direction is consistent with the direction indicated by the sensor to obtain the correct output signal.

The advantages of CHIPSENESE AN3V current sensor are not more than these.

Dimensions of CHIPSAENSE AN3V current sensor:

Monitoring and control process

1. Real-time monitoring: The main current flows through CHIPSENSE AN3V current sensor primary pin, and the Hall element inside the sensor senses the magnetic field and converts it into a differential voltage signal (Vout-Vref) proportional to the current.

2. Signal transmission: The differential voltage signal is transmitted to the ADC (analog-to-digital converter) input pin of the MCU.

3. Intelligent analysis: The algorithms in the MCU analyze the signals sampled by the ADC in real time to determine whether the current is within the normal range, whether there is an overload or abnormality.

4.Quick action: Once the MCU determines that the current abnormality exceeds the safety threshold, it immediately outputs a control signal to drive the main circuit contactor or relay to disconnect. The entire process can be completed in a very short time (microseconds to milliseconds), effectively protecting the equipment. CHIPSENSE not only save costs, but also provide more efficient current sensors.

Application value

The AN3V hall effect current sensor form CHIPSENSE has been adopted by many mainstream charging pile manufacturers, significantly improving the current monitoring accuracy and response speed of the equipment. CHIPSENSE’s excellent temperature stability and reliability can maintain high-precision measurement even under severe working conditions, providing a solid technical guarantee for the stable, efficient and reliable operation of the charging pile, CHIPSENSE current sensor helps to reduce equipment maintenance costs.

5. The introduction of CHIPSENSE AN3V series current sensors

AN3V series is a high-performance open-loop hall effect current sensor product line launched by CHIPSENSE, which is specially designed to meet the needs of high precision, high reliability and high consistency in the fields of power supply, photovoltaic, energy storage, electric vehicle charging, etc. The series current sensors of CHIPSENSE has been fully optimized and upgraded in materials, structure and design, and at the same time has excellent cost performance. It is the preferred solution for localization.

CHIPSENSE AN3V current sensor through automated production.

Main models: CHIPSENSE AN3V PB35, AN3V PB55 current sensor and so on.

Measurement range: covering the rated value of ± 80A to ± 200A, with a maximum measurable value of ± 375A.

Core features:

Open-loop current measurement principle based on Hall effect.

There is a high level of electrical isolation between the primary side (high current side) and the secondary side (signal side).

Raw materials compliant with UL 94-V0 flame retardant grade are used.

No insertion loss (does not affect the main circuit).

Low voltage supply: + 3.3V or + 5V.

Ultra-thin design: height h = 8.7mm.

Key parameters:

Typical accuracy: ± 1%

Response time: 2.5μs (extremely fast)

Insulation withstand voltage: meets the requirements of relevant safety standards.

Bandwidth: 250kHz (wideband sound)

Linearity: ≤ 0.5%

Operating temperature: -40 ° C to + 105 ° C (wide temperature range)

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806