We have now entered the era of Industry 4.0, where artificial intelligence technologies are propelling the manufacturing sector towards intelligent and flexible transformation. As a core component of smart manufacturing, the control precision of robotic servo systems directly impacts production efficiency and product quality. Current sensors, serving as the ‘sensory nerves’ of servo systems, are pivotal for AI algorithms to achieve precise control. Traditional open-loop current sensors suffer from issues such as insufficient accuracy, significant temperature drift, and slow dynamic response, rendering them inadequate for meeting modern industry's demands for efficiency, safety, and intelligence. In this context, CHIPSENSE CR1V closed-loop Hall-effect current sensor emerges as an ideal choice for industrial automation upgrades, owing to its high precision, rapid response, and superior insulation properties.

This paper will delve into the technical characteristics of the CR1V closed-loop Hall-effect current sensor from CHIPSENSE and explore how it enables precise control and real-time monitoring within AI-driven industrial applications, particularly in robotic servo systems.

I.Current Monitoring Challenges in Robot Servo Systems

In robotic servo systems, current monitoring presents the following challenges:

1. Dynamic response requirements: During rapid start-stop and variable-speed operations of servo motors, significant current fluctuations necessitate sensors with high bandwidth (e.g., 200kHz) and low latency (tracking time ≤1μs).

2. Accuracy and stability: The precision of current measurement directly impacts the control accuracy of servo motors and system stability.

3. Safety Requirements: Within industrial environments featuring high voltages and substantial currents, sensors must exhibit robust insulation and protective capabilities.

4. Environmental Adaptability: Factors such as temperature, humidity, and electromagnetic interference in industrial settings impose heightened demands on sensor performance.

5. Integration and Reliability: Compact design facilitates seamless system integration, alongside the capacity for long-term stable operation under harsh conditions including elevated temperatures.

CHIPSENSE current sensor has developed corresponding solutions to address these challenges.

II. AI-Driven Industrial Applications: The Evolving Role of Current Sensors

1. Trends in the Application of AI within Industrial Automation

Artificial intelligence technology is reshaping industrial automation, enabling autonomous decision-making, predictive maintenance and optimised control of equipment. Real-time, high-precision data acquisition forms the foundation for AI algorithms to function effectively, with current sensors serving as a critical data source that directly impacts the accuracy and real-time performance of AI models.

2.The Critical Role of Current Sensors in AI Applications

Real-time data acquisition: AI algorithms require high-frequency, low-latency current data to enable millisecond-level control adjustments. For instance, in robotic arm servo systems, current fluctuations may indicate load changes or mechanical jamming; AI analyses this data to adjust motion trajectories and prevent damage.

Data Quality Requirements: AI models are highly sensitive to data accuracy and stability. Current sensors with high precision and low temperature drift ensure reliable input data for AI.

Edge Computing Integration: Modern industrial systems increasingly run AI algorithms on edge devices (such as PLCs or industrial gateways), demanding sensors that are compact, low-power, and easily integrated.

3.How CHIPSENSE CR1V current sensor Supports AI-Driven Industrial Applications

High-precision data: Closed-loop Hall effect technology ensures linearity and repeatability in current measurement, delivering high-quality datasets for AI training.

Multi-range flexibility: CHIPSENSE current sensor 6A/15A/25A multi-range design accommodates current ranges across diverse industrial equipment, from compact collaborative robots (Cobots) to large industrial machinery.

Safety and reliability: AI systems depend on sensors' long-term stable operation. The CHIPSENSE CR1V current sensor’s insulated design and wide temperature tolerance ensure uninterrupted data acquisition in harsh environments.

4.In light of recent developments

Industrial Internet Platforms: How domestic and international industrial internet platforms (such as Siemens MindSphere and Huawei FusionPlant) integrate high-precision sensor data to achieve comprehensive intelligent plant management.

5G + AI + Industrial Sensors: The low-latency characteristics of 5G networks combined with the current sensor of CHIPSENSE CR1V's rapid response accelerate the deployment of the Industrial Internet of Things (IIoT).

Policy and Standards: Reference requirements for intelligent sensors outlined in China's ‘Made in China 2025’ initiative or the EU's Industry 5.0 framework, emphasising the current sensor of CHIPSENSECR1V's alignment with industry development trajectories.

CHIPSENSE current sensor has also evolved in step with the times.

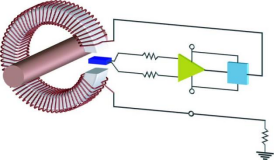

III.Operating Principle of Closed-Loop Hall Current Sensors

1.Fundamentals of the Hall Effect

The Hall effect describes the phenomenon whereby a voltage difference arises across a conductor when current flows through it whilst situated within a magnetic field. This principle finds extensive application in current measurement.

2. Closed-Loop (Compensation) Design

Closed-loop Hall sensors employ feedback coils to compensate for magnetic fields in real time, eliminating hysteresis and temperature drift to achieve high-precision current measurement. Compared to open-loop sensors, closed-loop designs offer significant advantages in accuracy, linearity, and response speed.

3. Key Technical Parameters

Gain error: Deviation between measured and actual values.

Non-linearity error: Non-linear relationship between sensor output and input current.

Temperature drift: Effect of temperature variation on measurement accuracy.

Frequency bandwidth: Maximum frequency to which the sensor can respond.

IV.Technical Features of CHIPSENSE CR1V PB00 Series Current Sensors

CHIPSENSE CR1V PB00 series current sensors employ an insulated primary-secondary design, conforming to international standards including IEC 60664-1 and IEC 61800-5-1. Its insulation withstand voltage test reaches 2.5kV (50Hz, 1min), with a transient withstand voltage of 9kV, creepage distance of 15.5mm, and electrical clearance of 6.35mm, ensuring safe operation in demanding industrial environments. CHIPSENSE current sensor have a good performance in it.

2. Electrical Performance

Multi-range design: CHIPSENSE current sensors, CR1V 6 PB00 (±6A), CR1V 15 PB00 (±15A), CR1V 25 PB00 (±25A), catering to diverse servo system power requirements.

High Accuracy: Measurement precision of ±0.7%, with temperature drift limited to ±0.05%/°C.

Rapid Response: Response time of just 1μs and bandwidth of 200kHz, suitable for high-dynamic industrial environments.

3. Environmental Adaptability

Wide temperature range: Operating temperature -40°C to 85°C, storage temperature -40°C to 125°C.

Flame-retardant materials: The housing material of all CHIPSENSE current sensors complies with UL 94-V0 flame-retardant standard.

4. Mechanical and Installation

Compact dimensions: 21.91mm × 19.80mm × 11.50mm, facilitating integration.

Standardised interfaces: 6-pin primary-side connection, 3-pin secondary-side signal connection.

V.Application Solutions for CR1V Current sensor from CHIPSENSE in Robot Servo Systems

1. Real-time Monitoring

CHIPSENSE CR1V current sensor achieves real-time current acquisition and feedback through a 200kHz bandwidth and 1μs response time, delivering precise control data for servo systems.

2. Precision Control

Combining AI algorithms with the high-precision current data provided by the CR1V optimises servo motor control strategies, enhancing system dynamic performance and stability.

3. Safety Protection

The CR1V's insulated design of CHIPSENSE current sensor effectively prevents electrical faults, safeguarding both the system and personnel.

4. Case Study

Within a robotic production line, CHIPSENSE CR1V current sensors were deployed to monitor current fluctuations in servo motors. Through real-time data acquisition and AI analysis, the system predicts motor overload risks and automatically adjusts operational parameters. This approach reduced equipment failure rates by 30% and minimised downtime by 40%.

VI. Comparison with Similar Products

| Comparison Item | CHIPSENSE CR1V Closed-Loop Hall Sensor | Open-loop Hall sensor | Other closed-loop sensors (e.g., famous big brand) |

| Accuracy | ±0.7% | ±1% to ±3% | ±0.5% to ±1% |

| Response Time | 1μs | 5μs to 10μs | 1μs to 3μs |

| Insulation Performance | 2.5kV Insulation Withstand Voltage | 1kV to 2kV | 2kV to 3kV |

| Price | High Cost-Effectiveness | Low | High |

CHIPSENSE CR1V current sensor offers significant advantages in precision, response speed and insulation performance, whilst being 100% domestically manufactured to maintain high cost-effectiveness, making it well-suited for industrial automation upgrade requirements.

VI.Risk Warnings and Usage Recommendations

1. Installation Precautions: Ensure no conductive parts of the sensor are exposed, adhering to IEC 61800-5-1 standards to prevent electric shock and equipment damage.

2. Environmental Restrictions: Avoid prolonged operation in environments exceeding 85°C to maintain reliability.

3. Maintenance Recommendations: Periodically inspect insulation resistance and terminal connections to ensure long-term stable operation.

VII.Conclusion and Outlook

CHIPSENSE CR1V closed-loop Hall current sensor offers a dependable current monitoring solution for industrial automation upgrades, owing to its high precision, rapid response, and superior insulation properties. With the continuous advancement of AI and robotics technology, CHIPSENSE CR1V current sensor holds promising prospects for application in smart manufacturing. We encourage practitioners in the industrial automation sector to explore the CR1V current sensor of CHIPSENSE in their projects and contact manufacturers for bespoke solutions, collectively driving the intelligent evolution of industrial automation.

Article Tags: # Industrial Automation #Hall Effect Current Sensor #Robotic Servo Systems #AI Real Time Monitoring #CR1V Closed Loop Sensor #Precision Control# CHIPSENSE

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806