In the pursuit of the "double carbon" goal, wind energy is one of the main forces of clean energy, and its stable and efficient operation is directly related to the security of energy supply and power grid. Inside this behemoth, the precise "sensory nervous system" is silently guarding the smooth transmission of every current. Today, let's talk about this sensory nervous system - high-precision current sensing. Taking CHIPSENSE CS3A Current Sensor for reference.

Current monitoring challenges for wind turbine operation

The wind in nature is the so-called changeable and unpredictable. The fan is always faced with frequent start and stop of wind speed. When starting, the fan is impacted by large current, which may trigger the over-current protection mechanism.; In addition, it is also subject to external disturbances such as thunderstorms, and transient high voltage may also damage the equipment. In addition, inside the fan, there are problems such as over-current, short circuit, and insulation aging. Therefore, the fan needs to accurately measure the DC/AC/pulse current in real time, which requires the detection device to have high insulation, low temperature drift, and fast response.Therefore, CHIPSENSE current sensors must overcome these difficulties and produce high-quality current sensors that meet customer needs.

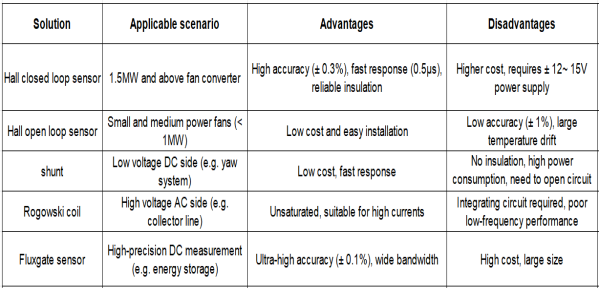

Comparison of common fan current detection schemes:

Scenario analysis and selection recommendations:

1.5MW fan converter: Hall closed-loop sensors (such as CS3A 100 P00 current sensor of CHIPSENSE) are usually used to measure ± 100A DC current and cooperate with PLC to achieve over-current protection.

3MW offshore wind turbine: salt spray resistance, high insulation, optional enhanced Hall sensor or fiber optic current sensor.

Low voltage control circuit: Shunt can be used, but insulation isolation measures need to be installed.

1.5MW fan: The rated current of the converter is about 500A, and multiple CHIPSENSE CS3A 100 P00 current sensor parallel or a single high current sensor (such as CS3A 200 P00 from CHIPSENSE) can be selected. 5MW fan: requires a range of ≥ ± 300A, CHIPSENSE CS3A 125 P00 current sensor or customized solutions are recommended.

Offshore fans: Select sensors with UL94-V0 housing and salt spray-resistant design. Highland fans: Ensure that the operating temperature covers -40 ° C (such as the CS3A series).

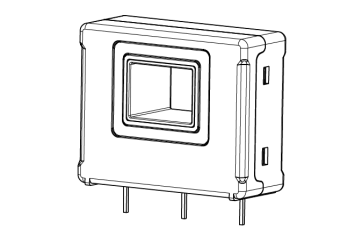

When space is limited, a compact closed-loop sensor (e.g. CS3A current sensor, 25.4 x 36.5mm) is preferred.

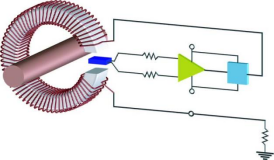

Brief Description of Hall Effect Closed Loop Current Sensor

The magnetic field generated by the primary current Ip and the output current I generate the same magnetic field on the compensation coil, and the direction is opposite. The Hall inductive device and the processing circuit together with the compensation coil output the current Ip, and the output current I accurately reflects the magnitude and direction of the measured current. Since the magnetic core works in a zero magnetic flux state, the nonlinearity and remanence of the magnetic core have no effect on the accuracy of the current sensor, so the Hall closed-loop current sensor has high accuracy and small nonlinear distortion.

Technical features:

bandwidth

High measurement accuracy

Fast response

Low temperature drift

Very good nonlinear distortion

No insertion loss

Fan failure prevention and the role of sensors

1. Overcurrent protection

The sensor monitors the converter current in real time, and when the current exceeds a preset value (e.g. 1.2 times the rated current), triggers a protection mechanism to cut off the fault loop.

2. Insulation monitoring

Through creepage distance and insulation withstand voltage design, prevent leakage risk.

Periodically conduct insulation withstand voltage tests to ensure the stability of the sensor's performance.

3. Dynamic response

High bandwidth (150kHz) to cope with di/dt shocks caused by wind speed changes and avoid false triggers.

Introduction to CS3A current sensor of CHIPSENSE

CS3A P00 series is a closed-loop (compensated) current sensor based on Hall principle independently developed by CHIPSENSE, with a rated range from 50A to 125A, which can be used to measure DC, AC and pulse currents.

Characteristic

A Closed-Loop (Compensation) Current Sensor Based on Hall Principle

Insulation between primary and secondary sides

Raw materials comply with UL 94-V0

Excellent linearity

Exceptional accuracy

Low temperature drift

No insertion loss

Execution standards:

IEC 60664-1:2020

IEC 61800-5-1:2022

IEC 62109-1:2010

Applications:

AC variable speed and servo motor drives

Uninterruptible Power Supplies (UPS)

Static converters for DC motor drives

Switch Mode Power Supplies (SMPS)

Power supplies for welding applications

Battery management

Wind energy inverter

Test and detection devices

Parameter characteristics

current output

Power supply voltage: ± 12V~ ± 15V

Rated range: ± 50~ 125A

Measuring range: ± 90~ 200A

Working range: -40~ 85 ° C

Typical accuracy: ± 0.3%

Response time: 0.5 μs

Insulation voltage: 3kV

Transient withstand voltage: 7kV

Electrical Clearance/Creepage Distance: 6.7mm

Bandwidth: 150kHz

Linearity: 0.2%

Selection case:

1.5MW fan converter:

Selection: 3 pcs CHIPSENSE CS3A 100 P00 current sensors parallel connection, total range ± 450A (residual capacity).

Installation: The secondary output is connected to the PLC analog input, and the SCADA system is uploaded through Modbus.

Calibration: Use Fluke 773 to verify accuracy annually to ensure that the error is less than or equal to 0.5%.

3MW offshore wind turbine:

Selection: CHIPSENSE CS3A 125 P00 current sensor or customized high insulation models.

Notes: Install heat sinks to ensure that the bus temperature is less than or equal to 100 ° C.

Selecting the right sensor not only enhances detection accuracy, but also prolongs equipment life and reduces operation and maintenance costs.

CHIPSENSE CS3A current sensor application frame diagram in fan

Conclusion:

At present, we are moving towards the era of intelligent wind power, and the refinement of every basic technology, especially the current sensor as the "sensory nerve" of the fan, should consolidate the sensory foundation in order to ride the wind and contribute more green power.

CHIPSENSE is also accompanying the development of the times, manufacturing current sensors that meet customer needs.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806