Multiple photovoltaic cells (PV), connected in series and parallel, form a high-voltage photovoltaic battery pack. Connect the inverter and start grid-connected power generation; connect the MPPT and start charging the battery pack to store energy.

600V and above high voltage PV has a GFDI requirement. GFDI is the abbreviation of Ground Fault Detection Interrupter (Ground Fault Detection and Interruption). Note that it is not a common leakage protection device GFCI (Ground Fault Circuit Interrupter). The purpose of GFDI is not to protect human safety, but to prevent various failures of equipment caused by faulty grounding of equipment - such as power loss, phantom voltage, stray voltage, etc. The purpose of GFDI is to protect equipment.

The key ideas of GFDI are:

1.For the safety of life, it is best to ground the positive end and the metal shell; but this can cause so-called PID (potential-induced attenuation) problems.

2.Negative grounding is an effective means of suppressing PID; however, it is necessary to monitor the leakage current of GFDI to avoid short circuits due to faulty grounding and/or ground faults.

The key objective of GFDI is to detect abnormal grounding risks on the DC side; safety standards such as UL1741 and IEC62109 also require GFDI when the voltage of the photovoltaic system is ≥ 600V, and the fault response time is ≤ 2 seconds.

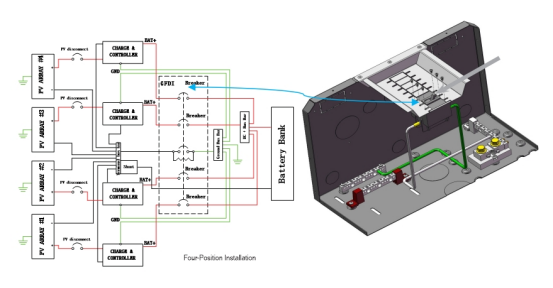

Here is a GFDI circuit for a high-voltage battery pack that relies purely on a mechanical Breaker to disconnect the system and protect it from faulty grounding.

The advantages are significant: high reliability.

There are also obvious disadvantages:

1.High cost: a special GFDI breaker is required, and procurement risks are also introduced;

2.The response time is slow (the effect of current heating through the resistor is used to make the Breaker trip, which is an I2t relationship), and the detection accuracy is relatively low.

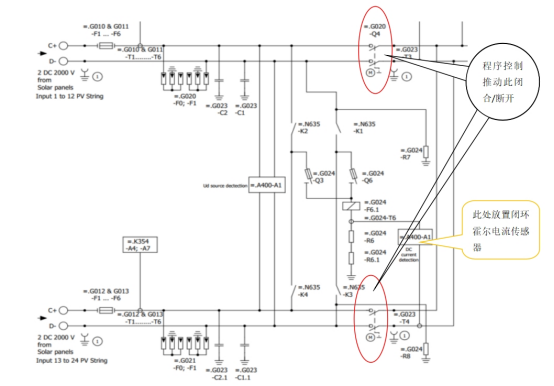

In view of the advantages and disadvantages of the above products, CHIPSENSE improved GFDI circuit is proposed as follows. Its innovation is to introduce a closed-loop Hall current sensor to monitor the leakage current in real time. The program continuously performs A/D conversion and makes logical judgments. Once it exceeds a certain limit (the minimum requirement of IEC is 5A. But the size of this value can be arbitrarily set in the program), outputs a control signal, and quickly trips the device. The entire response time is less than 100ms (0.1s), which is far less than the minimum requirement of IEC is 2s. CHIPSENSE made it.

Now let's explain why we can respond within 100ms (0.1S).

1.CHIPSENSE Closed-loop Hall current sensors use CM series current sensor dedicated to photovoltaics and energy storage, such as CHIPSENSE CM2A current sensor, CM3A current sensor, 0~ 200A range, with an accuracy of 0.3%. After zero point elimination is done well; low temperature drift, high-precision resistance, self-calibration and other measures are selected for the sampling and amplification circuits at the back end, the accuracy can be easily better than 0.1%, or even better than 0.05%. This is why CHIPSENSE current sensors have some advantages.

2.The response time of CHIPSENSE current sensors is less than 1us, which means accurate measurement and rapid response.

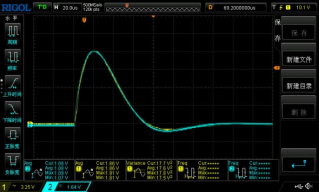

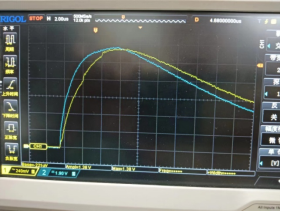

Figure shows:di/dt=50A/us

Taking a single-chip microcomputer with an 8051 core of 8 Bit with a main frequency of 12Mhz and a 1T instruction cycle as an example, CHIPSENSE completes an A/D conversion cycle. The fastest is only about 6us, and the slowest is about 35us. The program judges that 100 machine instructions are required, which takes about 100us = 0.1m. The final output controls the on-off of the contactor, and the maximum operation time of the contactor is about 60ms, with a total maximum of about 61ms; CHIPSENSE current sensor saves time and cost for customers to a large extent.

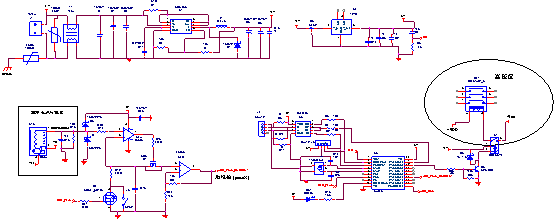

The complete application circuit of CHIPSENSE is as follows. Each subunit has been independently verified for its accuracy. The circuit has also been operated for a long time and has been proven to be stable and reliable.

When CHIPSENSE main power supply 24V input, with EMC protection part, this design of CHIPSENSE can resist at least 2000V EFT and surge. The main CPU is 8051 core, with a standard 485 interface. The output is through a 10A touchpoint capacity relay to finally push a high current DC contactor, so as to achieve the purpose of protection.

The innovation of the circuit is that it comes with a maximum detection and hold circuit. CHIPSENSE tests show that the unit circuit can smoothly detect the pulse amplitude with a width of only 10us and maintain it for at least 10 seconds. The program only needs to read the A/D value at this point regularly, without worrying about missing the maximum moment, so it does not need to care about the running speed of the micro-controller. The above circuit, even if the main frequency of the micro-controller is as low as 1Mhz, the overall response speed will be faster than 65ms. This unit circuit is a highlight from CHIPSENSE.

CHIPSENSE CM2A/CM3A Hall effect current sensor has an operating voltage of ± 15V, which may not be very friendly for a single-chip system because it only uses a single 5V/12V power supply.

In this case, CHIPSENSE CS1V current sensor can be considered, as shown in the figure below. The device is powered by a single 5V supply, closed-loop Hall effect, PCB mounted, threaded, and measures up to 300A. The response time of the device is about 1.2 us.

It is also a good choice to use CHIPSENSE current sensor to measure the leakage current of GFDI. Only need to pay attention to: insulation considerations, the device of this structure, the voltage of the measured line, can not be too high, CHIPSENSE will provide customers with different options.

Response time

CS1V Current sensor

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806