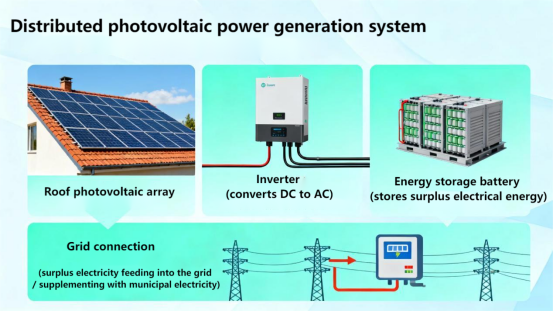

With the in-depth advancement of the "Dual Carbon" strategy, China's photovoltaic industry has experienced explosive growth, and by the first half of 2025, the cumulative installed capacity in China is expected to exceed 1000 GW, marking the entry of China's photovoltaic sector into the terawatt era. The household photovoltaic market is also flourishing everywhere; however, behind this booming development, small current monitoring issues have quietly become a critical bottleneck restricting system efficiency and safety. The National Energy Administration's document No. 7 [2025] "Management Measures for the Development and Construction of Distributed Photovoltaic Power Generation" clearly requires that household photovoltaic projects must achieve technical standards that are "observable, measurable, adjustable, and controllable." This policy emphasizes:

Household photovoltaic systems (380V/220V voltage levels) need to monitor key parameters such as current and voltage in real-time to ensure efficient and safe operation of the system;

Power grid companies need to establish a warning mechanism for the available capacity of the distribution network to enhance the capacity for integrating distributed photovoltaic systems into the grid;

New projects must meet the requirements of being "observable and measurable", while existing projects should gradually be upgraded to enhance their informatization and intelligence levels.

Requirements for small current monitoring accuracy: In household photovoltaic systems, the monitoring accuracy of small currents in the range of 10-50A directly affects MPPT efficiency. According to a report from the China Photovoltaic Industry Association in the first half of 2025, the average comprehensive energy efficiency loss of the system (including inverters, sensors, cables, etc.) is around 10%-15%. Among them, insufficient sensor accuracy (such as an error of >±2%) often makes it difficult to accurately capture current changes in this range, potentially leading to a distortion in system efficiency assessment and ultimately resulting in a 3%-8% loss in MPPT efficiency. This may also lead to delayed fault warnings and other issues. More concerning is that when photovoltaic systems share monitoring circuits with devices such as electric vehicle charging stations, blind spots in small current monitoring can easily trigger safety hazards. However, the research and development of the CHIPSENSE current sensor takes a series of safety issues into consideration.

Insulation safety risks: The household environment has strict requirements for electrical safety. Sensors must meet standards such as IEC 60664 and IEC 61800 to ensure compliance with insulation withstand voltage, creepage distance, and other indicators.

Installation and integration difficulty: Household inverters have limited space, requiring compact and easily installable sensors to simplify system design.

The following are common current monitoring solutions used in residential photovoltaic systems:

| Parameter items | Open-loop Hall (taking CHIPSENSE AN5V as an example) | Closed-loop Hall sensor | Shunt |

| Accuracy (10-50A) | ±1% | ±0.1% - ±0.5% | ±0.5% - ±1% |

| Volume | 19×16.2×6mm | Typically ≥ 30×30mm | Depending on power, usually larger requires |

| Insulation grade | 300V/600V CAT III | Typically 100V-500V | Additional insulation design |

| Power consumption | Low (no insertion loss) | Medium (compensation circuit required) | High (noticeable heating) |

| Cost | Low | High | Low |

| Applicable scenarios | Household photovoltaic, charging piles, UPS | Industrial High precision measurement | Large current industrial scenarios |

Technical description:

Although the closed-loop Hall sensor has an accuracy of ±0.1%-0.5%, it is expensive and large, making it suitable for industrial scenarios; the shunt has an accuracy of ±0.5%-1%, but there are issues with insertion loss and heat generation.

The ±1% accuracy of CHIPSENSE AN5V series current sensor is sufficient to meet the MPPT requirements in residential photovoltaics, and it has significant advantages in terms of insulation safety, size, and cost.

The AN5V series is a current sensor independently developed by CHIPSENSE, based on an open-loop design utilizing the Hall effect, with electrical insulation between the primary and secondary sides, ensuring measurement accuracy and system safety. CHIPSENSE this series current sensor includes multiple models with a range from 15A to 60A, and can withstand a maximum primary busbar temperature of 85°C, along with excellent electromagnetic interference resistance, perfectly adapting to the complex operating environment of residential photovoltaic systems. With the following technical advantages, it meets the compliance and safety requirements for small current monitoring in residential photovoltaic applications.

1.Core technical parameters

| Parameters | Specifications(CHIPSENSE AN5V 10-60 PB00) | Complies with standards/policy requirements |

| Accuracy | ±1%(25°C,10-50A range) | Meets the 'measurable' requirement, controlling MPPT efficiency loss within 1% |

| Insulation Withstanding Voltage | 3.0kV AC withstand voltage,,6.0kV Impulse withstand voltage

| Complies with IEC 60664-1、IEC 61800 |

| Creepage Distance | 5.5mm(Primary and second) | Meets 300V/600V CAT III insulation level |

| Volume | 19×16.2×6mm | Suitable for compact residential inverters |

| Response Time | ≤3μs | Applicable for dynamic current monitoring |

| Operating Temperature | -40°C to 85°C | Adapts to extreme outdoor/indoor environments |

2.Application Scenario Analysis

Household Photovoltaic Inverters

Monitoring small currents on the DC side improves MPPT efficiency. A certain photovoltaic operation and maintenance provider in Shandong reported that after using CHIPSENSE AN5V 15 PB00 current sensor, the inverter MPPT efficiency increased from 92% to 97%, and the annual power generation increased by about 5% (Data source: CHIPSENSE’s customer feedback, June 2025).

Electric Vehicle Charging Piles:Real-time monitoring of leakage currents to prevent safety hazards. Compatible with AC/DC charging scenarios, CHIPSENSE current sensors are meets the national standard GB/T 18487.1 requirements.

Risk Warning and Compliance Recommendations

1.Risk Notice:

The temperature of the original busbar in the household environment should not exceed 100°C to avoid overload.

During installation, ensure that conductive parts are not exposed to prevent the risk of electric shock.

2.Compliance Recommendations:

Strictly adhere to IEC 61010-1 safety standards to ensure that sensor installations meet application standards.

Regularly calibrate sensors to ensure monitoring accuracy.

Conclusion

CHIPSENSE AN5V series hall current sensors, with ±1% high precision, a 5.5mm creep distance, and a small size of 19×16.2×6mm, are an ideal choice for monitoring small currents in residential photovoltaic systems and charging piles. With the promotion of new regulations by the National Energy Administration, their technological advantages help to address industry pain points, enhance system efficiency and safety, and meet the requirements of being "observable, measurable, adjustable, and controllable." CHIPSENSE current sensors have advantages in these aspects.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806