At 2 am on April 25, 2025, in the duty room of a 100MW.h energy storage power station in East China, Mr.Wang, who was dozing off, was awakened by the sudden alarm of the BMS system. When he rubbed his confused eyes, he saw that the abnormal voltage fluctuation of a battery pack on the big screen was significantly greater than that of other battery clusters. If the judgment is misjudged, the whole station will face a loss of hundreds of thousands of yuan for maintenance. If the judgment is missed, it will face a greater risk of thermal runaway. At this time, Mr.Wang, who was completely sleepy, quickly took out his mobile phone and remotely called CHIPSENSE VN2A voltage sensor to collect wave-forms at 10kHz. After a few minutes, he locked the abnormal battery cluster and took corresponding measures, and the system resumed normal operation.

Why did CHIPSENSE VN2A voltage sensor withstand this speed of life and death?

In solar energy storage power plants, the main factors affecting battery life include the following aspects:

Overcharge or over-discharge: Deep discharge can cause greater pressure on the battery, and frequent deep charge-discharge cycles can shorten the battery's lifespan; high charge-discharge rates can cause more heat to be generated inside the battery, which may damage the battery structure and affect its lifespan. Therefore, CHIPSENSE has done a lot of new research in charging.

Temperature: Too high or too low temperature will affect the performance and life of the battery. High temperature will accelerate electrolyte decomposition, electrode material degradation, accelerate battery aging, and may also lead to the risk of thermal runaway; high temperature also intensifies battery self-discharge, and long-term high temperature will lead to deep discharge of the battery; low temperature will lead to battery performance attenuation and structural damage, reducing battery efficiency and capacity. CHIPSENSE also has unique technology in product temperature control.

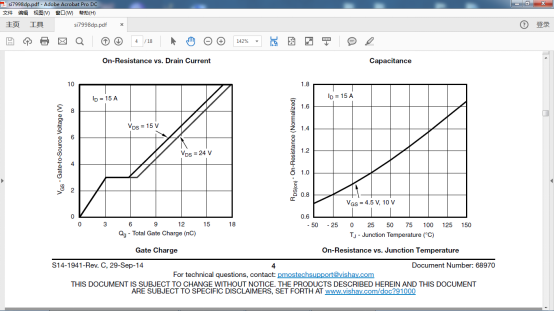

Poor battery management: For example, high-frequency harmonics issues: when the PCS switching frequency exceeds 10 kHz, the delay of traditional devices exceeds 100 µs, resulting in a sharp increase in false positives, causing maintenance delays.

CHIPSENSE VN2A voltage sensor response measures:

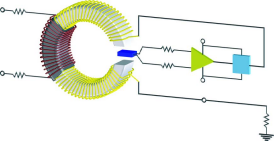

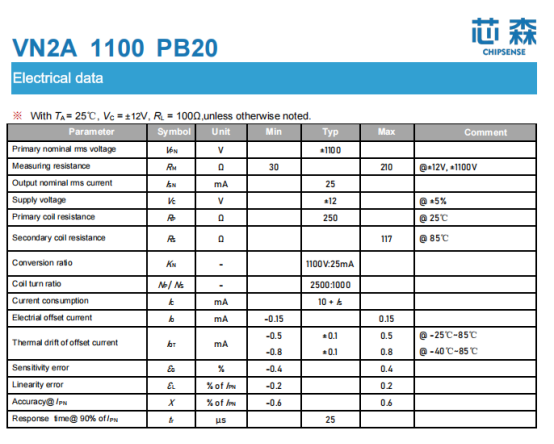

Closed-loop Hall + compensation technology: The combination of CHIPSENSE technology makes the measurement of current and voltage more accurate and reliable. In solar cell systems, CHIPSENSE voltage sensors achieve precise control by monitoring the voltage changes of the battery at different temperatures in real time, combined with temperature data, to prevent overcharging or overdischarging, thereby optimizing battery status, extending life and improving system stability.

-40℃~ 85℃ full temperature zone drift < 0.1 mA: CHIPSENSE can ensure high accuracy and stability under various temperature conditions, whether it is the large temperature difference between day and night in the northwest desert, or the high temperature and humidity in the Southeast China Sea, CHIPSENSE measured voltage data can be maintained with high accuracy, providing accurate data for the system, improving system efficiency and prolonging battery life.

25µs Tracking Delay: Enables fast response and optimizes energy acquisition and storage.CHIPSENSE Voltage sensor and BMS for closed-loop control. Adjustment of charging and discharging parameters through real-time feedback to accommodate changes in the state of the battery. CHIPSENSE low-latency feature helps to improve the stability and efficiency of the system.

Application Case:

Case 1: 55W power tower and solar monitoring system for ports and shipping

Problem: In the traditional solution, the diode will cause energy loss. The maximum measured output of the 55W solar panel is only 36W, and the diode loss is as high as 1.4W. It brings a burden to the battery. Continuous rainy weather causes the battery to be over-discharged and accelerates battery aging. CHIPSENSE technical team is dedicated to solving this problem.

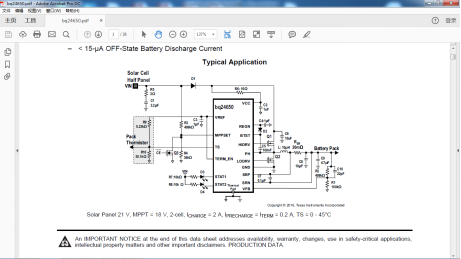

Modification: CHIPSENSE VN2A 25 P00 voltage sensor is selected to cooperate with the relay (or other shutdown circuit). When the input voltage is detected to be lower than the MPPT set voltage value, the circuit is automatically disconnected to protect the battery assembly, thereby reducing the ineffective energy consumption. The total power consumption of the two devices form CHIPSENSE is only 30mA, which can support 15 days of rainy battery life, effectively prolonging the battery life.

Case 2: A booster station in Yangjiang city, Guangdong

Problem: The 2 kV peak voltage generated during the charging process caused frequent damage to the voltage divider + isolation op amp equipment used in the original plan, and multiple sets of equipment were burned out in half a year. CHIPSENSE knew about this problem for the first time and then proposed a solution.

Transformation: Replace it with a high accuracy VN2A voltage sensor of CHIPSENSE, directly hook the high-voltage busbar, 4.1 kV withstand voltage + UL94-V0 level shell flame retardant, safe operation for two years, and increase the battery cycle life from 4000 to 5500 times, CHIPSENSE greatly improves the stability and economy of the system.

Case 3: Tibet Optical Storage Project

Problem description: In Tibet’s photovoltaic storage project, when the night temperature was as low as -30℃, the traditional sensor caused the battery state (SOC) to jump as high as 15% due to zero drift, which caused the dispatch center to misjudge it as a "virtual power" phenomenon, affecting the stability and economy of the system. They asked CHIPSENSE for help.

Solution: Replace the CHIPSENSE VN2A voltage sensor, its excellent low temperature drift characteristics reduce the SOC measurement error to less than 2%. This improvement improves the accuracy of measurement, CHIPSENSEN not only improves the reliability and efficiency of the system, but also reduces the number of starts and stops of diesel generators. According to statistics, it can save hundreds of thousands of yuan in fuel costs every year. CHIPSENSE current sensor saves cost for customers to a large extent.

Conclusion

Through the effective use of CHIPSENSE voltage sensors, accurate monitoring of battery voltage can be achieved, and real-time adjustment of charge and discharge parameters combined with closed-loop control and BMS can be achieved to optimize battery usage strategies. At the same time,CHIPSENSE data analytic is used for preventive maintenance and temperature compensation technology is adopted to ensure measurement reliability under various environmental conditions, thereby prolonging battery life and improving system efficiency. So CHIPSENSE is the best partner for long-term cooperation with many customer.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806