As of 2025, the cumulative installed capacity of photovoltaics in China has exceeded 800GW, and as the first batch of large-scale photovoltaic power plants enter the retirement period, more than 500,000 tons of waste modules are added every year, and the value of silver paste contained in it is as high as 10 billion yuan. However, the current industry silver paste collection rate generally hovers between 85% and 92%, and a large number of precious metal resources are buried in landfills due to technical bottlenecks. This battle of resource recycling and economic benefits is forcing the innovation of sensing technology - precision measurement equipment represented by CHIPSENSE current sensors is reshaping the value chain of photovoltaic recycling.

CHIPSENSE current sensor is based on the mature Hall effect principle and realizes accurate current monitoring through non-contact magnetic field measurement. In the field of photovoltaic module recycling, CHIPSENSE’s technical value is mainly reflected in process optimization and resource recovery efficiency improvement. The following is an analysis of its core value from three dimensions: technical principle, application scenario and measured effect:

Technical principle: open-loop and closed-loop dual-path innovation

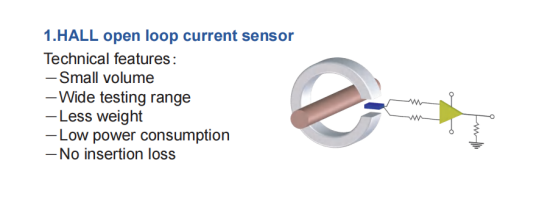

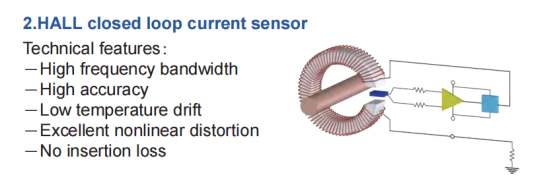

CHIPSENSE current sensors use a dual-track technology architecture to cover mainstream Hall current detection solutions.

1.CHIPSENSE Open-loop detection (simplified version of structure) gathers the magnetic field generated by the measured current through the magnetic ring, and the Hall element detects the change of magnetic flux at the air gap. The advantage is that the response speed is fast (the frequency width is up to 20kHz), the cost is low, and it is suitable for real-time monitoring of large current fluctuation scenarios such as photovoltaic crushers. For example, in the component crushing process, it can capture±35% current fluctuation, helping the equipment to dynamically adjust the power load.

2.CHIPSENSE Closed-loop detection (high-precision version) Adds a feedback coil to offset the primary magnetic field and achieve a zero flux balance state. The measurement accuracy reaches 0.5%, which is especially suitable for micro-ampere current detection scenarios such as silver paste electrolytic purification. After a recycling company in Suzhou adopted this scheme, the detection error of silver ion concentration in the electrolyte was reduced from ± 5ppm to± 0.3ppm.

Key technological breakthroughs in photovoltaic recycling

In the silver paste recycling process, the sensor solves two core problems:

1. Crusher energy consumption control Traditional crushing equipment frequently overloads the motor due to current fluctuations. Real-time monitoring of the motor working current through Hall sensors, combined with PID algorithm to dynamically adjust the speed:

In a 10MW module recycling line in Hebei, the power consumption per ton of processing was reduced from 3.2kWh to 1.8kWh.

Abrupt current response time ≤300ms to avoid equipment idling loss

2.Micro-short-circuit silver paste captures the residual silver paste on the glass substrate (thickness 10-15μm), which will generate micro-ampere leakage current. The closed-loop Hall sensor can detect the current change of 0.5μA, and cooperate with the image recognition system to locate the silver paste area ≤0.1mm ². After the application of an enterprise in Zhejiang province, the collection rate of the silver paste in the sorting process increased by 7.2%, and the annual increase benefit exceeded 5 million yuan.

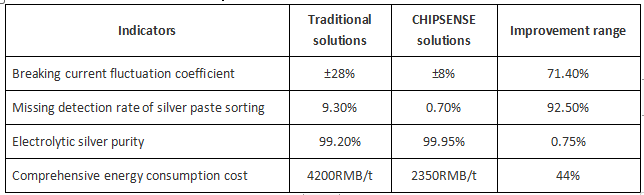

Measured data and industry validation

In the city Ningxia 20MW module recycling demonstration project, CHIPSENSE current sensors demonstrate multi-dimensional value:

The project has passed the TÜV Rheinland certification, and the comprehensive collection rate of silver paste is 97.1%, which is a qualitative leap compared with the industry average (89% -92%).

Technology extension and industrial adaptation

CHIPSENSE conducts special project optimization for photovoltaic recycling scenarios:

1. The operating temperature range of the wide temperature range stability sensor is extended to -40℃ ~ + 85℃, suitable for extreme environments such as the Northwest Gobi Desert

2. Anti-interference design adopts dual magnetic ring differential detection technology to increase the electromagnetic interference rejection ratio to 60dB

3. The digital interface RS485/Modbus protocol is directly connected to the PLC system to realize a closed loop of data in the whole process of crushing, sorting and smelting.

In a high-altitude photovoltaic power station recycling project in Qinghai, the CHIPSENSE current sensor operated continuously for 3,000 hours without failure at an altitude of 4,500 meters and a temperature difference of 40℃ between day and night, verifying its industrial-grade reliability.

Industrial value redefinition

The involvement of Hall current sensors from CHIPSENSE is reconstructing the economic model of photovoltaic recycling.

1. The cost of electricity is reduced. Through precise energy consumption management, a single production line can save more than 1.50 million yuan in electricity costs

2. Precious metal premium capture every 1% silver paste collection rate, 10,000 tons of processing capacity can increase 800-12 million yuan.

3. Optimized carbon footprint reduces silver mining demand, reducing carbon emissions by 2.1 tons of CO2 equivalent per ton of component recovery.

According to brand New Energy Finance, the global photovoltaic recycling market will exceed 100 billion by 2030, of which silver paste will account for more than 25%. By deeply integrating fundamental physical principles with industrial scenarios, CHIPSENSE is providing the foundation for accurate measurement of this resource revolution.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806