Driven by the "double carbon" goal, our country's new energy development has grown steadily. According to the latest data from the National Energy Administration, as of the end of July, the country's cumulative installed power generation capacity was 3.67 billion kilowatts, an increase of 18.2% year-on-year. Among them, the installed capacity of solar power generation was 1.11 billion kilowatts, an increase of 50.8% year-on-year. The rapid expansion of clean energy has not only enhanced the security of power supply, but also seen from the side that our country has put forward higher requirements for the energy efficiency level of power equipment.

Air conditioning is one of the essential household appliances in our daily life. But the traditional fixed frequency air conditioner is known as the "power consumption king", which has become a "stumbling block" for users to turn on the air conditioner for a long time. Therefore, more power-saving inverter air conditioners have emerged. This article attempts to discuss how current sensors can help the inverter air conditioner compressor to precisely control the frequency, so that the inverter air conditioner can operate efficiently, quietly and reliably. CHIPSENSE current sensors play an important role in many aspects of daily life.

What is an inverter air conditioner?

The variable frequency air conditioner is an air conditioner that controls the cooling/heating capacity by adjusting the speed of the compressor through the frequency converter. Compared with the traditional fixed frequency air conditioner, the motor can adjust the working frequency in real time according to the load change to avoid temperature fluctuations and energy waste caused by frequent start and stop. The energy efficiency level is significantly improved through the variable speed operation mode, which mainly consists of three parts: the frequency conversion controller, the frequency conversion motor and the air conditioner. CHIPSENSE current sensor plays a certain role in it.

Why must inverter air conditioners "sense" current?

1.Torque generation logic of permanent magnet synchronous compressor

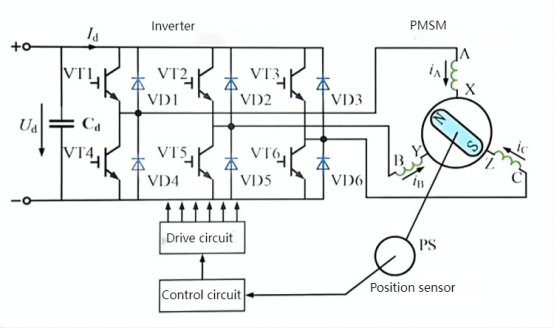

At present, the mainstream inverter air conditioners on the market use permanent magnet synchronous motors (PMSM/BLDC). The main control methods of permanent magnet synchronous motors are: vector control, frequency converter control, large Hall drive, asynchronous start. The core of vector control of permanent magnet synchronous motors is current loop control, which controls the d-axis (excitation current) and q-axis (torque current) respectively through the PI regulator. The q-axis current Iq directly determines the electromagnetic torque; the d-axis current Id affects the flux linkage and is used for weak magnetic diffusion.

If the sampling error exceeds ± 0.5%, the torque fluctuation at low speed and light load will be amplified into mechanical vibration, and the "hum" sound recognizable by the human ear will appear; the loss of control in the weak magnetic field ID will bring additional copper consumption, directly lowering the seasonal energy efficiency ratio (SEER).

2. The triple task of current sampling

A) Closed-loop control: The current loop bandwidth is usually set to 1/10 to 1/5 of the switching frequency (about 400 to 800 Hz at 4 kHz switching). For every 10 µs increase in sampling delay, the phase margin decreases by about 4 °, which is very easy to induce howling.

B) Hardware protection: Over-current, stall, and phase loss must be triggered by the hardware comparator within 1 to 2 PWM cycles, otherwise the IGBT/SiC module is at risk of tube explosion.

C) Energy efficiency measurement: The new national standard GB 21455-2023 for air conditioners requires a deviation of less than 3% between the measured APF and the nominal value; sampling drift will cause the cumulative power of the software to be inaccurate, ultimately making the product unable to pass the sampling inspection.

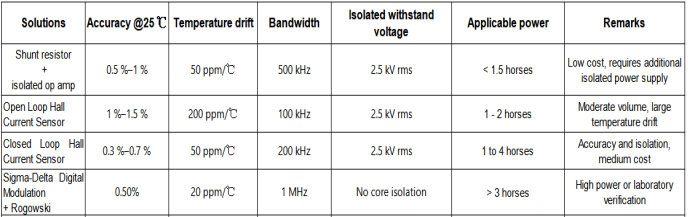

The optional current detection route of the air conditioner compressor driver board:

Under the constraint of "no increase in BOM complexity", closed-loop Hall current sensors can become the mainstream choice for 1-3 horsepower household inverter air conditioners:

The effective bandwidth above 200 kHz can cover 8-16 kHz SiC inverters.

- 2.5 kV rms reinforced insulation meets IEC 60335-1 type test without additional isolation of DC-DC.

The full temperature error within 0.7% accuracy can be directly converted into a gear increase of SEER 0.02 W·h/W·h.

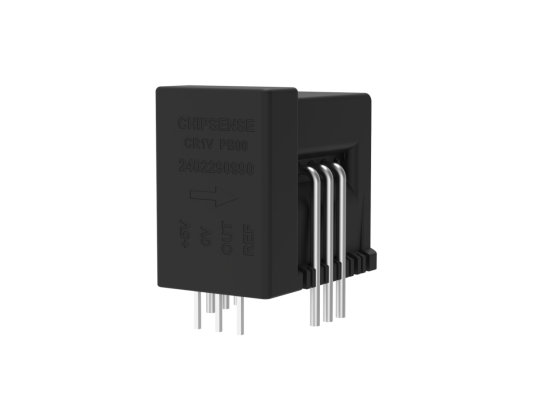

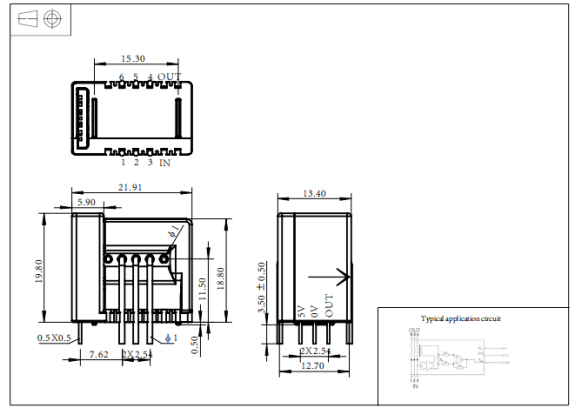

Introduction to CR1V PB00 Current Sensor of CHIPSENSE

CR1V PB00 current sensor is a closed-loop (compensated) current sensor based on Hall principle independently developed by CHIPSENSE, which can measure DC, AC and pulse currents, with ranges of 6A, 15A, 25A, and can also be customized according to the needs of different application scenarios of customers. This is also one of CHIPSENSE’s unique services.

Characteristic

A Closed-Loop (Compensation) current sensor based on hall principle

Insulation between primary and secondary sides

Raw materials comply with UL 94-V0

Excellent linearity

Excellent accuracy

Low temperature drift

No insertion loss

Execution standards:

IEC 60664-1:2020

IEC 61800-5-1:2022

IEC 6 2109-1: 2010

Industrial application field

AC frequency conversion speed regulation, servo motor

Uninterruptible power supply (UPS)

DC Motor Driven Static Converter

Switching Power Supply (SMPS)

Welding machine power supply

Battery management

Wind energy inverter

Test and measurement equipment

Parameter characteristics:

voltage output

Power supply: + 5V

Measuring range: 6~ 25A

Working range: -40~ 85 ° C

Accuracy: 0.7%

Response time: < 1μs

Insulation voltage: 2.5kV

Transient withstand voltage: 9kV

Bandwidth: > 200kHz

Linearity: 0.2%

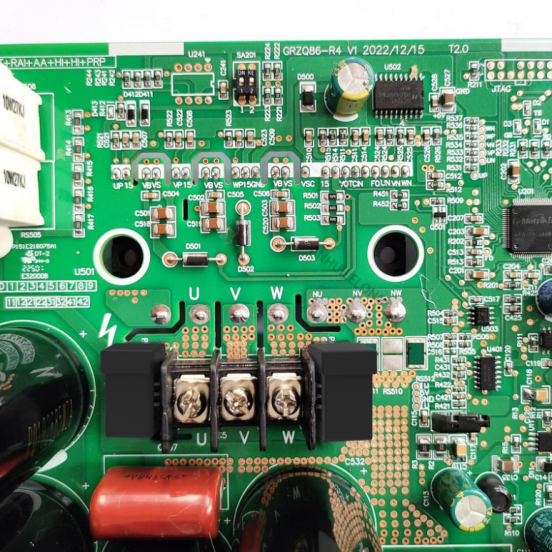

Engineering examples of CHIPSENSE CR1V series Current Sensor

1.Mapping relationship between technical parameters and air conditioning conditions

Range: CHIPSENSE CR1V 6 PB00/15 PB00/25 PB00 current sensor corresponds to the peak current of 1/1.5/3-horse compressor;

Output: 2.5 V ± 0.625 V, can be directly connected to a 3.3 V ADC without further amplification or level shifting.

Offset drift: ± 0.05 mV/℃ Under the limit conditions of outdoor heating at -20 ° C and heat sink at 55 ° C, the current zero point only drifts by 0.1% to avoid low-frequency "humming";

Tracking time: 1 µs (90% step response), ensuring over-current protection can be triggered within 2-3 PWM cycles.

CHIPSENSE current sensors are produced and put into market according to strict requirements.

2.System-level revenue (taking 1.5-hp DC conversion as an example)

Energy efficiency: When the compressor is operating at a low frequency of 20 Hz, the torque ripple decreases by 0.3 N · m, the input power decreases by about 4 W, and the SEER increases by 0.02 W · h/W · h, which can make the whole machine span gears.

Mute: The current ripple energy is concentrated towards the high frequency, and the sound pressure in the 1-2 kHz band is reduced by 2-3 dB (A), meeting the C-mark mute certification.

Compliance: The whole machine has passed the IEC 60335-1 reinforced insulation type test, no additional isolated power supply is required, and the cost is reduced by 2-3 yuan. CHIPSENSE current sensor saves costs for customers to a large extent.

3.Integration Considerations

Busbar wiring: Maintain the 6.35mm electrical clearance on the primary side to avoid 1-2% additional error caused by eddy current proximity effect;

Ground plane: secondary 2.5 V reference co-ground with MCU ADC, digital ground/analog ground single point connection to prevent switching noise coupling;

Failure rate: 1500 mΩ insulation resistance @500 V, 85 ° C/85% RH acceleration after 1000 h drift < 0.1%, to meet the 10-year design life.

Conclusion

When GB 21455-2023 pushes the SEER threshold up again and consumers become more critical of silent ears, the current sampling of the drive board of the air conditioner compressor needs to be "accurate in every inch, and the volume must be compared."

Closed-loop Hall technology, with its balance of bandwidth, isolation, and temperature drift, is recognized as a viable path in the industry, while the 6-25A range, 2.5 V midpoint output of the CR1V series current sensor from CHIPSENSE falls right into the sweet spot of air-conditioning controllers - no additional calibration, no changes to the BOM structure, and "current sensing" can be done without compliance, reliability, and enough silence. CHIPSENSE current sensors not only meet customer requirements, but also save costs and improve happiness value for customers.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806