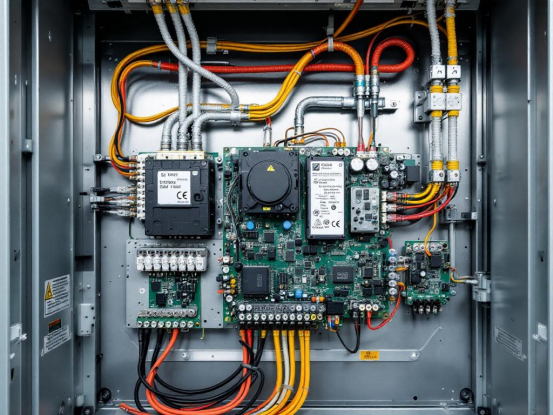

The general design life of onshore wind turbines is 20 years. After entering the "14th Five-Year Plan", our country's wind power has ushered in a new wave of retirement and replacement. It is predicted that there will be more than 1,800 units in 2025, with an installed capacity of 1.25 million kilowatts. The issuance of the "Wind Farm Transformation, Upgrading and Decommissioning Management Measures" issued by the National Energy Administration is to provide a timely policy for the transformation and decommissioning of these units. The "Management Measures" propose to encourage the "equal capacity transformation" of wind turbines to improve equipment performance and efficiency. This paper attempts to discuss how to introduce a monitoring system to extend the life of the unit and improve power generation efficiency. CHIPSENSE current sensor will play an important role.

What is "equal capacity transformation"?

Wind farm transformation and upgrading mainly refers to the replacement or technical transformation of on-site wind turbines, supporting boost substations, on-site collector lines and other facilities. It is usually divided into two types: capacity enhancement and equal capacity transformation. Capacity enhancement aims to increase the power generation capacity of wind farms, while equal capacity transformation mainly improves equipment performance and efficiency without changing the total capacity. CHIPSENSE has been constantly developing.

Why are current sensors at the heart of intelligent monitoring of wind turbines?

The operation status and power generation performance of wind turbines depend on accurate current monitoring of generators, frequency converters, power units, etc. Current changes are often early signs of failure - bearing wear, insulation aging, abnormal pitch drive, etc., which can be seen by analyzing the current waveform.

For more than 20 years old fans, due to long-term operation, the sensor is bound to age, resulting in increased temperature drift, decreased accuracy, large measurement deviation, slow response, and insufficient anti-interference ability. All fan renovations should bear the brunt of replacing old sensors.

A Hall current sensor with high bandwidth and micros response time can capture the transient current changes of the fan under high-speed operating conditions, providing a real-time and accurate data basis for predictive maintenance. CHIPSENSE is also offer it.

Cost reduction: reduce downtime losses and manual inspections

In traditional old wind farms, due to the lack of advanced monitoring devices, equipment inspections rely more on labor, and each unit may need dozens of manual inspections to climb the tower every year, which is not only costly, but also poses safety risks. Equipped with current sensors from CHIPSENSE, the current status of key points such as generator stator and inverter input busbar can be monitored in real time in the unit control system, and an alarm signal can be automatically issued when abnormal, and maintenance can be arranged in advance to reduce unplanned shutdown inspections. At the same time, maintenance is only possible if there is a problem, CHIPSENSE current sensor greatly reduces labor costs for customers.

Efficiency: Optimizing power output and energy management

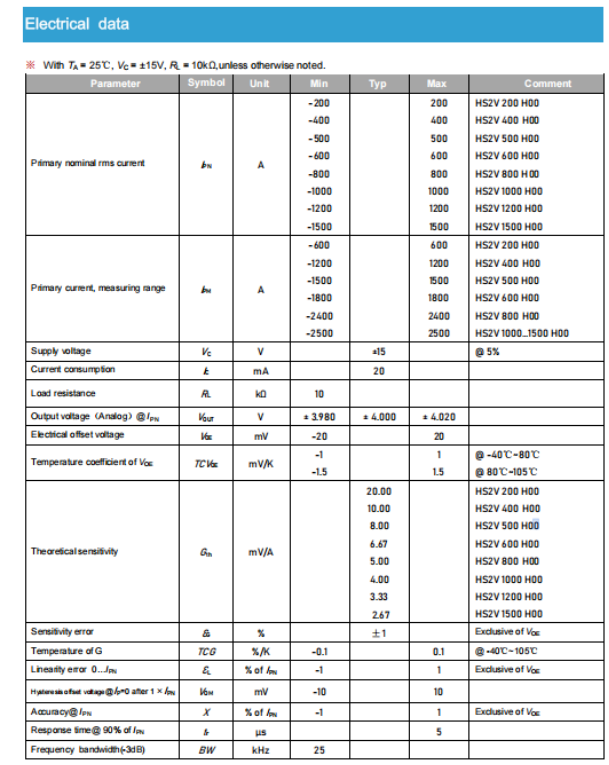

"Equivolumetric transformation", the fan generally needs to be replaced with more efficient software and hardware systems such as blades, generators, and control systems, but to maximize the performance of the unit, accurate operating data is also required. For example, a current sensor with ± 1% (IPN) measurement accuracy and ± 4 V analog output can help the controller adjust the pitch angle, generator excitation, and grid connection strategies in real time, so that the unit can maintain the optimal power curve under different wind speed conditions.

If it can be equipped with a modern intelligent monitoring platform, current data can be integrated with meteorological, vibration, temperature, and other multi-source data to achieve:

Power curve online calibration

Low wind speed power generation optimization

Grid-connected power smoothing control

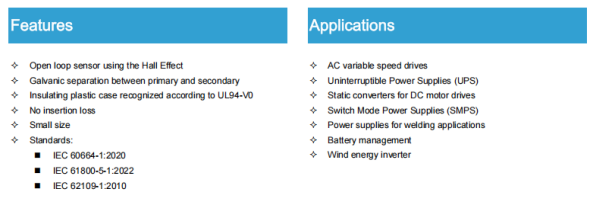

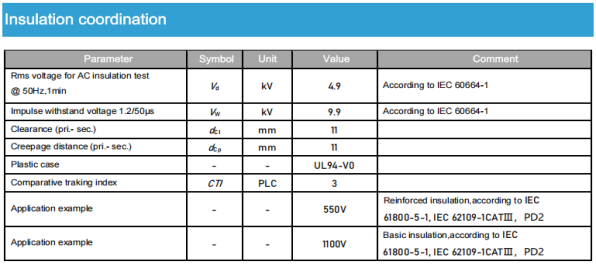

Design to Adapt to Harsh Working Conditions of Wind Power

Fans usually work in high humidity, high salt spray, and poor high temperature environments such as seaside and mountainous areas. The durability of the sensor is crucial. Generally, it is necessary to have a wide temperature working range, high power frequency isolation voltage and high flame retardant shell.

These characteristics ensure that the sensor remains stable and reliable in the fan compartment for many years. This is the basic requirement of CHIPSENSE.

Domestic current sensor selection recommendation

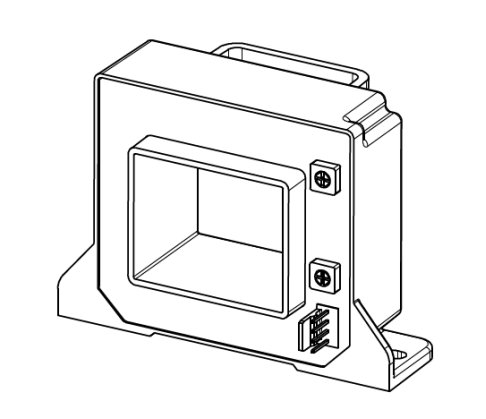

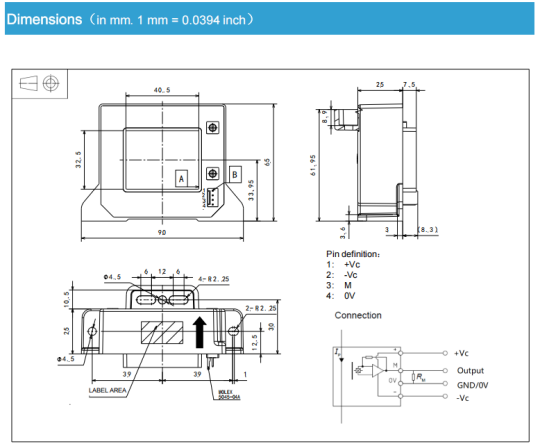

Based on Hall principle, CHIPSENSE HS2V H00 series current sensor supports DC, AC and pulse current measurement, and realizes electrical insulation between primary and secondary sides. CHIPSENSE has saved costs and increased benefits for many customers.

The superposition of policy and technology

In the "equal capacity transformation" mode encouraged by the "Management Measures", the current sensor is not only a hardware component, but also a data source for the intelligent monitoring system. By integrating CHIPSENSE HS2V H00 current sensor into the wind turbine electrical link, the wind farm can:

Increase annual power generation

Extend equipment lifespan

Reduce lifecycle operation and maintenance costs

In the future, with the advancement of intelligent transformation of wind turbines, current sensors are expected to become the standard of wind power "health management", just like equipping wind turbines with a 24-hour "intelligent medical examiner". CHIPSENSE will be one of them.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806