With the implementation of distributed energy storage projects, the "Bidirectional current" of the power system is becoming a hot word in the industry. From the "source-charge" unidirectional power supply to the "source-storage-charge" multi-dimensional interaction, two-way inverters and battery management systems (BMS) are playing an unprecedented important role. Behind this transformation, higher requirements are also placed on the accuracy, response speed and safety insulation performance of current monitoring.

It is in this context that CHIPSENSE CR1V series closed-loop Hall current sensor has become the preferred solution for many energy storage integrators and PCS manufacturers.

Unlike traditional inverters, bidirectional inverters in energy storage systems need to be able to convert grid electrical energy into DC energy storage, and also efficiently invert the DC power released by energy storage back to AC power. Frequent switching of charge and discharge and dynamic and drastic changes in operating conditions make current monitoring equipment must have the following capabilities:

Accurate sampling of positive and negative bidirectional currents: both charge and discharge states

High-speed response, millisecond action protection: against battery abnormalities and bus voltage fluctuations

Strong electrical isolation and high safety level: meeting the stringent reliability requirements of high-voltage energy storage systems

Temperature drift control and small linear error: ensure consistency in long-term operation.

CR1V series current sensor of CHIPSENSE adopts closed-loop Hall compensation architecture, which has the characteristics of high-speed response, high precision, good linearity, and small temperature drift. It is very suitable for high-precision acquisition of current in energy storage inverters and BMS.

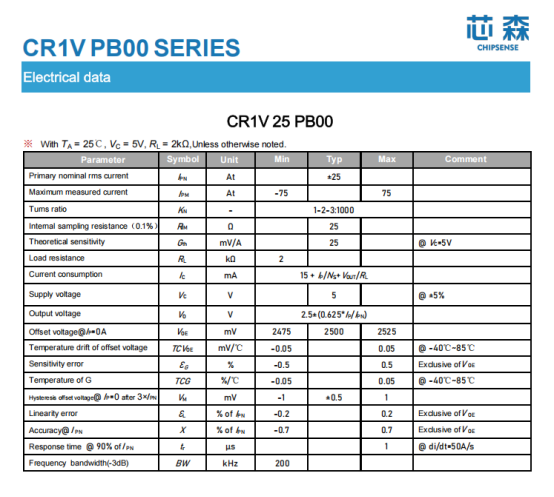

In the actual operation of the energy storage system, even the milliamp deviation will affect the SOC estimation and battery management strategy over a long period of time. The accuracy of CHIPSENSE CR1V current sensor can reach within ± 0.7% under full scale, and the linear error is less than ± 0.2%, providing a stable and reliable data basis for system operation.

The energy storage inverter needs to quickly sense and control the current between the power grid, battery and bus. The response time of CR1V current sensor from CHIPSENSE is only 1μs, which can easily cope with the di/dt change above 50A/μs. At the same time, it has 200kHz bandwidth, which is suitable for high-frequency control systems and improves the dynamic performance of the system.

CHIPSENSE CR1V current sensor provides three specifications: 6A, 15A, and 25A, and outputs the standard voltage signal (2.5V ± 0.625V), which is convenient for the system to directly sample and access. At the same time, the design without insertion loss can avoid energy waste and circuit interference, and does not affect the loop load, simplifying the electrical design of the system.

The working voltage of the energy storage system is usually between 300V and 600V, which places strict requirements on the electrical isolation capacity. CHIPSENSE CR1V current sensor has an effective isolation voltage of ≥ 2.5kV, which meets the application under the industrial level 3 pollution level (CATⅢ PD2) to ensure the safety of personnel and equipment.

Application example: CHIPSENSE Typical configuration in lithium battery energy storage PCS + BMS combination.

In a distributed industrial and commercial energy storage project, CHIPSENSE CR1V current sensor is simultaneously deployed in:

The DC bus sampling of energy storage converter (PCS) is used to control the limited viewership of charge and discharge.

Battery pack BMS main circuit sampling to achieve charging protection, short circuit detection and energy metering;

Bidirectional DCDC converter link, energy flow dynamic regulation monitoring.

The actual operation shows that the charging and discharging switching response of the system is compressed from 5ms to 2ms, and the SOC error is reduced to less than 1.2%, CHIPSENSE current sensors significantly improves the energy efficiency and battery life.

Conclusion: In the era of distribution and storage, the value of current sensors is being reassessed

From MIIT encouraging "new energy distribution and storage" to the State Grid exploring a new model of "source, network, load and storage integration", the trend of intelligent power systems is becoming more and more obvious. As a key underlying sensing component of energy storage systems, the importance of current sensors is constantly amplified. CHIPSENSW is also constantly improving product quality and customer service.

Based on cutting-edge current sensing technology, CHIPSENSE CR1V series empowers new energy architectures such as optical storage integration and storage and charging integration. In the future, CR1V current sensor of CHIPSENSE will continue to iterate to help more projects achieve "accurate control, precise calculation and stable using".

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806