The DC screen converts AC power into stable DC power through the rectifier module, providing DC power supply for equipment in substations, power plants, IDC data centers, etc. After the AC power supply is interrupted, the battery can still supply power to the equipment to protect the normal operation of the equipment. DC screen batteries are generally used in parallel with multiple groups of batteries. During use, if there is a short circuit between the battery groups or the capacity difference is too large, it is easy to cause mutual "backflow" current, causing the busbar to overheat, the fuse to break or even the equipment to be damaged. So, how to prevent this phenomenon from happening? This paper explores a feasible technical path for the protection of limited viewership of DC screen battery packs through current sensors. It will take CHIPSENSE current sensor as an example.

1.Hidden danger of DC screen parallel battery and protection requirement of limited viewership

In the battery parallel operation mode, the total voltage is the same as the voltage of a single battery, and the total current is the sum of the current of each battery. For example, after four 12Ah batteries are connected in parallel, the total capacity is 48Ah, and the total voltage is still 12V. After the battery is connected in parallel for a long time, if there is a voltage difference, or a certain group of internal short circuits, or the aging of the battery pack causes the resistance difference to be too large, or human error causes a short circuit/short circuit, etc., in these cases, the current may flow rapidly from the high-voltage battery to the low-voltage battery, or the healthy battery pack will charge or discharge quickly to the fault branch, the instantaneous current may far exceed the rated value, and if there is a lack of effective current detection, it may cause serious damage in an instant. Therefore, there must be current limiting protection between the battery packs, and the fault branch will be cut off as soon as the over-current occurs.CHIPSENSE products are also required according to this standard.

2.Comparison of common technical solutions for limited viewership protection

CHIPSENSE current sensor solution:

To protect the limited viewership of parallel battery packs, common technical solutions include:

| Solution | Advantages | Disadvantages |

| Fuse | low cost, simple structure | Slow response, non-resettable, needs to be replaced after failure |

| Fuse protector | Possessing a certain breaking ability | Unrecoverable after action, high maintenance cost |

| Mechanical circuit breaker | Reusable, strong breaking ability | Long response time (usually 10-20ms), making it difficult to cope with instantaneous over-current |

| Electronic protection (with sensor) | Fast response, programmable, and remote monitoring | The initial cost is high, and it is necessary to cooperate with the control unit |

Among them, the electronic protection scheme based on current sensor is widely used in high-reliability systems due to its advantages such as microsecond response, repeatable action, and support for intelligent control. So do CHIPSENSE.

3.Protection technology path based on limited viewership of current sensor

3.1.Technical principles

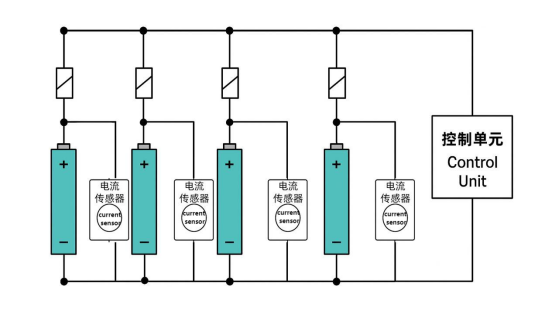

By installing an isolated current sensor on the positive or negative busbar of each battery, the branch current signal is collected in real time. The analog output of the sensor (such as 0-5V or 4-20mA) is connected to the Control Unit (such as PLC, protective relay or BMS), and the control logic determines whether overcurrent occurs.

Once the current is detected to exceed a preset threshold (e.g. 1.5 times the rated current), the control system immediately triggers the actuator (e.g. DC contactor or solid state relay) to cut off the fault branch, enabling fast limited viewership of protection. CHIPSENSE current sensors take this into account.

2. Sensor selection recommendations

To ensure the reliable operation of the system, the current sensor is recommended to meet the following basic performance metrics:

| Parameter | Recommendation request |

| Measurement type | Support DC, AC and pulse current |

| Isolated withstand voltage | ≥3kV AC,meets safety standards such as IEC 61010-1 |

| Response time | ≤10μs, support for fast failure response |

| Accuracy | Within ±1% (at rated current) |

| Temperature drift coefficient | ≤±0.5%/°C,ensure stability in a wide temperature environment |

| Measuring range | Covering 50A - 800A, suitable for different capacity systems |

| Installation method | Busbar perforated to reduce insertion loss |

| Operating temperature | -40°C ~ +85°C,adapt to the industrial environment |

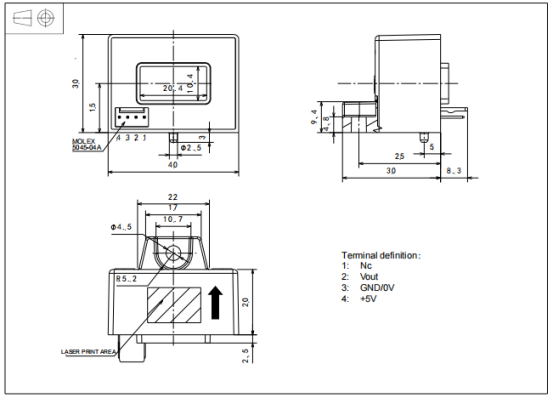

At present, there are a variety of Hall-effect open-loop or closed-loop current sensors available on the market that meet the above requirements (such as the AS1V series current sensor of CHIPSENSE), and the design should be comprehensively evaluated according to the system voltage level, spatial layout, and cost budget.

Installation Notes:

Range selection: The rated current is recommended to be 1.2 to 1.5 times the normal maximum working current;

Make the busbar fit tightly with the sensor via as much as possible to help improve the dynamic response characteristics.

Avoid parallel routing of sensor signal lines with strong interference power lines as much as possible to improve measurement stability.

In high-temperature or high-humidity environments, heat dissipation and insulation measures should be strengthened to prevent performance degradation.

Conclusion

With the continuous improvement of voltage level and capacity of DC power supply system, traditional passive protection components (such as fuses and Fuse protector) have been difficult to meet the needs of fast response and intelligent operation and maintenance. Electronic limited viewership of protection scheme based on current sensor, with its high precision, fast response, programmable control and other advantages, is becoming an important technical means of high reliability DC system.The current sensor of CHIPSENSE aims to meet the needs of its customers.

In the future, with the development of digital twins, edge computing, and AI prediction technologies, such monitoring systems are expected to evolve from "fault response" to "fault warning", further enhancing the intrinsic safety level of power systems.This is the goal that CHIPSENSE current sensor has always adhered to.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806