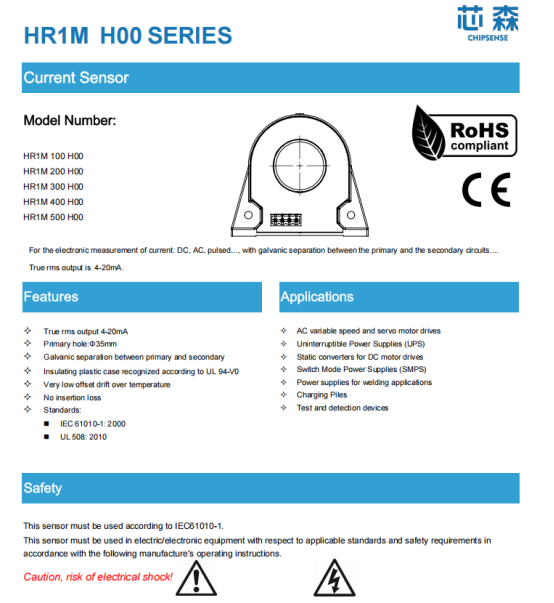

When an electric vehicle supporting 800V high-voltage fast charging is connected to the 800V super charging pile, the instantaneous inrush current may cause the failure of the inferior sensor. The charging gun overheats and melts, and the high-voltage breakdown catches fire... Behind these shocking safety accidents, there is often an easily overlooked component--current sensor. This paper attempts to explore how the CHIPSENSE electronic high-precision current sensor HR1M H00 series challenges this problem from a technical perspective.

The figure made by AI is for reference only.

Analysis of Difficulties in Current Monitoring of Overcharging System

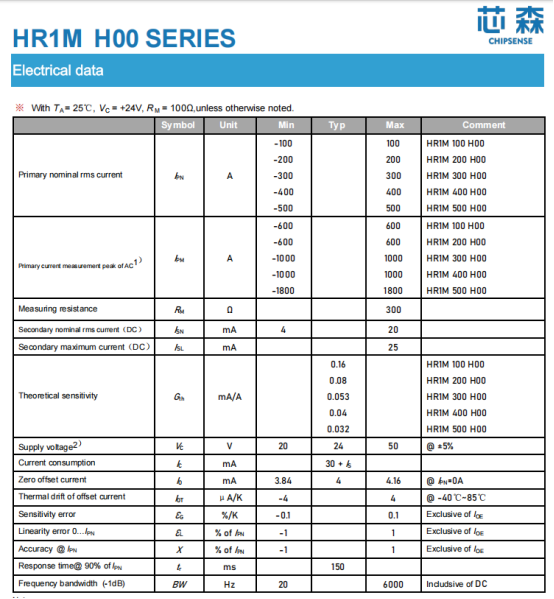

The continuous 500A + current (peak value exceeding 1000A) under the 800V high voltage platform poses four major technical requirements for the current sensor:

High precision dynamic response.

Low current detection requires high-precision current sensors, but the response speed is slow; high current detection is prone to electromagnetic interference causing data fluctuations, forming a contradiction between accuracy and response speed. The design of current sensors needs to balance this contradiction. This is what CHIPSENSE has been doing.

Strong insulation reliability

The transient surge voltage of the 800V system exceeds 3000V, and it needs to withstand a pulse voltage above 7kV;

CHIPSENSE asked the creepage distance of > 5mm and UL94-V0 flame retardant certification are required to prevent the risk of high temperature melting.

Extreme temperature stability

The working temperature of the busbar reaches 100 ° C, which is easy to cause temperature drift and affect the accuracy and stability of current sensor measurement.

Insufficient range coverage

Traditional current sensors can either only cover small currents or only large currents, making it difficult to achieve full-scale compatibility with 1A-500A, which can easily lead to blind spots in detection.So CHIPSENSE is committed to completing this.

Analysis of technology implementation of CHIPSENSE HR1M H00 series.

Core Performance Guarantee

| Parameter | HR1M 500 H00 indicator | Engineering application significance |

Theoretical sensitivity

| 0.032mA/A | 500Afull scale output 16mA |

| Linearity error | ≤±1% % of IPN | 500Acurrent detection deviation<±5A |

| Response time | 150ms(Type) | Overcurrent protection action time <200ms |

Frequency bandwidth (-1dB) | 20~6kHz | Capture charger IGBT switching harmonics |

Note: True RMS output (4-20mA) avoids measurement distortion due to AC distortion

Insulation safety design

Electrical clearance: 7.2mm - CHIPSENSE meets 300V CAT III PD2 (EN 61010-1)

Transient withstand voltage: 7.3kV (1.2/50 μs) - 2.4 times the margin required for systems over 800V

Material Certification: UL94-V0 Flame Retardant Housing - No Melting Risk at 100 ° C for Busbar.

Environmental adaptability

-40 ℃ - 85 ℃ working temperature range

Temperature Drift Compensation: Offset Current Temperature Drift ± 4μA/K

Fully sealed structure dustproof and moisture-proof (IP67 non-standard implementation, external protection is required)

Full scale current sensing

CHIPSENSE HR1M H00 series current sensor models are available from HR1M 100 H00 to HR1M 500 H00 current sensor, with rated current covering 100 to 500A and current measurement peak values from ± 600 to ± 1800A, which can meet the full compatibility requirements of overcharging systems on the market today. CHIPSENSE will keep it.

Key points of overcharging system deployment

1.Selection calculation

Peak current 1800A → choose CHIPSENSE HR1M 500 H00current sensor

Measurement resistance ≤ 300Ω (P3: Ru (max) = 300Ω)

2.Safety Installation Specifications

- Torque control: M5 screw 2.1N · m ± 10%

- Safety spacing: primary/secondary wiring spacing > 15mm (based on 7.2mm creepage distance 2 times redundancy)

- Strictly prohibit live operation

3.Circuit protection logic

sensor output → Control Unit → relay action

│ 4-20mA │threshold determination │ Response time<200ms

Measured data and optimization direction

Test report of an 800V charging pile manufacturer in Shenzhen.

| Working condition | Traditional sensors | HR1M 500 H00 |

| 500A continue 30min | ±8.2A error | ±4.3A error |

| 1000Ai mpact | output saturation | normal response |

Items to be optimized:

6000Hz bandwidth is insufficient for capturing SiC high-frequency switching ripple (the next generation requires > 10kHz)

- No native CAN communication requires an additional conversion module.

In summary, CHIPSENSE HR1M H00 current sensor provides an effective solution to the safety problem of overcharging system with its core advantages such as high precision and high stability. With the continuous expansion of the new energy vehicle market and the iterative upgrade of charging technology, the application prospect of HR1M H00 current sensor from CHIPSENSE is worth looking forward to

(Disclaimer: This article is based on publicly available information and is intended for information sharing. It does not constitute any investment or application advice. Please refer to the official documentation or consult a professional for specific product selection.)

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806