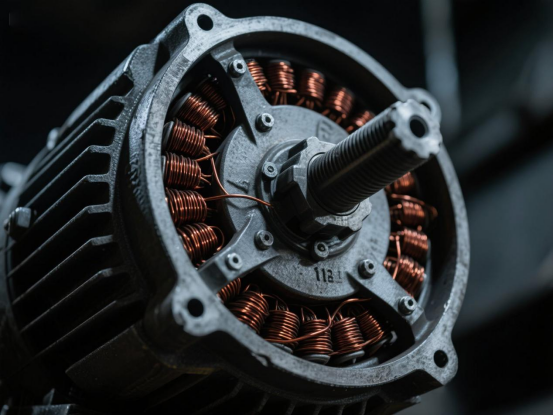

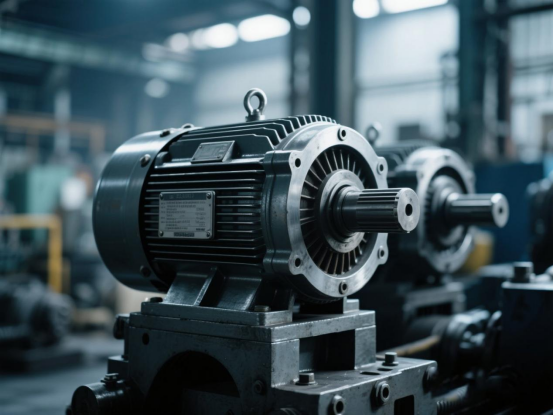

In August 2024, our CHIPSENSE team visited a new customer focusing on industrial automation equipment manufacturing. The customer provides production line automation solutions for many large manufacturing enterprises, and one of its core products is the three-phase AC motor drive system. With the advancement of Industry 4.0, in order to improve the performance and reliability of the three-phase AC motor drive system and achieve accurate monitoring and intelligent management of the motor running state, the customer decided to introduce a stable Hall current sensor to comprehensively upgrade the current monitoring link of the motor drive system. Therefore,CHIPSENSE became their choice.

With its deep technical accumulation and rich industry experience in the field of current sensors, CHIPSENSE has customized a current monitoring solution based on Hall current sensors for the customer's three-phase AC motor drive system. The solution adopts the high-precision Hall current sensor independently developed by CHIPSENSE, covering multiple key links such as motor three-phase incoming line current monitoring, motor winding branch current monitoring, and motor overload protection current monitoring. CHIPSENSE planned to provide corresponding product samples in November 2024, cooperate with customers to complete the preliminary sample testing process, and assist in the completion of the prototype of the motor drive system equipped with sensors.

Key link sensor application

Three-phase incoming current monitoring

At the three-phase incoming line of the three-phase AC motor drive system, a CHIPSENSE closed-loop Hall current sensor is installed. The sensor adopts the principle of closed-loop magnetic balance, which has the characteristics of high precision, wide measurement range, high linearity and good anti-interference ability. By monitoring the three-phase incoming line current in real time, the system can accurately grasp the input power of the motor, and detect the current imbalance and lack of equality abnormalities in time. For example, when there is a significant deviation in a certain phase current, CHIPSENSE sensor can quickly transmit the data to the control system, and the operation and maintenance personnel can take timely measures to avoid damage to the motor due to abnormal current, providing a strong guarantee for the stable operation of the motor.

Motor winding branch current monitoring

In order to ensure the normal operation of the motor windings, CHIPSENSE selects small, easy-to-install and high-resolution Hall current sensors to accurately monitor the current of each branch of the motor windings. These sensors can collect the current data of each branch in real time and transmit it to the data collection module. Through the analysis of the current of each branch, it can be judged whether there are potential faults such as local overheating and inter-turn short circuit in the motor windings. Once abnormal current changes are found, the system can issue an alarm in time to remind the operation and maintenance personnel to carry out maintenance, effectively prolonging the service life of the motor and reducing the equipment failure rate.

Motor overload protection current monitoring

CHIPSENSE open-loop Hall current sensor is deployed in the motor drive system for overload protection current monitoring. CHIPSENSE sensor has the characteristics of fast response, which can quickly detect the sharp rise of current in the moment of motor overload and transmit the signal to the protection device. When the current exceeds the set overload threshold, the protection device immediately cuts off the power supply of the motor to prevent the motor from burning due to long-term overload operation, escorting the safe operation of the motor.

Scheme design and planning

The technical team of CHIPSENSE had in-depth and close communication with the customer's design and R & D personnel. The technical team had a detailed understanding of the electrical architecture, motor parameters, operating conditions and monitoring requirements of the customer's three-phase AC motor drive system. Based on this information, a detailed sensor installation plan and system integration plan were formulated. In the installation plan, the rationality of the installation position of the CHIPSENSE sensor was fully considered to ensure that the sensor could accurately collect current data, while avoiding electromagnetic interference generated during the operation of the motor. In terms of wiring specifications, strict wiring standards were formulated to ensure the stability and reliability of signal transmission.

In addition, CHIPSENSE sensors are seamlessly integrated with existing motor control systems and monitoring systems, ensuring that the entire system can work together efficiently.

System testing and optimization

Before the system went online,CHIPSENSE and the customer jointly carried out a comprehensive and rigorous test work. The test content includes simulating current measurement under various motor operating conditions, overload protection function test, data transmission stability test, etc. When simulating motor heavy load start, sudden load, unload and other working conditions, verify whether the sensor from CHIPSENSE can accurately measure current changes and transmit the data to the control system in real time. Through multiple overload protection function tests, ensure that the sensor can respond in time when the motor is overloaded, and the protection device can operate accurately.

In the data transmission stability test, the transmission quality of the signal in the complex electromagnetic environment is checked, and some potential problems such as signal attenuation and interference are found and solved in time. After further optimization and improvement of the system, the entire current monitoring system can operate stably and reliably by CHIPSENSE.

Project results

In February 2025, the customer successfully won the bidding for the production line automation renovation project of a large manufacturing enterprise, which used a large number of three-phase AC motor drive systems. The customer officially placed an order for CHIPSENSE Hall current sensors, including a total of 2,500 Hall current sensors for three-phase incoming current monitoring, winding branch current monitoring and overload protection current monitoring. Through this cooperation, CHIPSENSE’s current sensor products have provided strong support for customers' product upgrades and market expansion with their excellent performance and reliable quality, and further consolidated CHIPSENSE’s market position in the field of industrial automation.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806