Recently, the Ministry of Natural Resources released data showing that in the first half of 2025, our country's marine GDP reached 5.10 trillion yuan, an increase of 5.8% year-on-year. Among them, the new grid-connected capacity and power generation of offshore wind power increased by 199.4% and 2.2% year-on-year respectively. With the acceleration of global energy transformation, our country's offshore wind power has ushered in rapid development, and a new type of floating wind power project has recently been intensively put into production. On July 10, 2025, Huaneng and Dongfang Electric developed the world's largest single-machine power 17 trillion-watt direct-drive floating wind turbine in Fuqing, Fujian, with an impeller diameter of 262 meters. It marks China's official leadership in the global floating wind power technology track.

CHIPSENSE also seized this opportunity to make innovations for the development of the times.

Floating wind power is an offshore wind power device that can float in water and capture wind energy to generate electricity. It uses dynamic submarine cables to transmit power. Its structure consists of: floating body module, anchoring system, power transmission and wind turbine configuration. The wind turbine is equipped with a typhoon-resistant unit, which can withstand up to 17 typhoons and has a maximum wind speed of 60 meters per second. Compared with general fixed offshore wind power, floating wind power can work at a distance of 100 kilometers from the coastline to provide power for deep sea operation areas. Installed 136 kilometers away from Wenchang, Hainan province "Haiyou Guanlan" installed capacity of 7.25 trillion watts, after production, the annual power generation of the fan will reach 22 million kWh, the electricity generated for oil and gas production, can save fuel nearly 10 million cubic meters of natural gas every year, while reducing carbon dioxide emissions 22,000 tons, environmental protection effect is remarkable.

Since floating wind power is operating in the deep sea, daily maintenance cannot be completed without manpower, and can only be maintained remotely. Deep-sea operation and maintenance is going through the era of intelligence, which requires the installation of various sensors. With the help of Beidou and other satellites, the power status of the entire floating wind power system and submarine cable can be monitored in real time. In floating wind power systems, the accuracy of current detection directly affects the efficiency and life of the system. Let's talk about how current sensors based on Hall effect can be efficiently applied in floating wind power

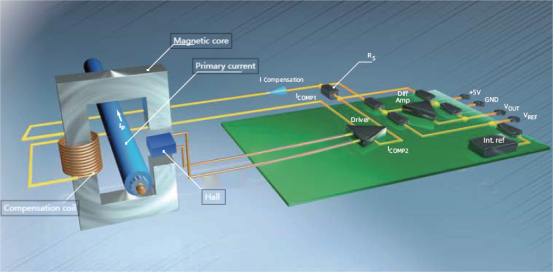

Hall closed loop current sensor

Working principle:

The magnetic field generated by the primary current Ip and the output current I generate the same magnetic field on the compensation coil, and the direction is opposite. The Hall inductive device and the processing circuit together with the compensation coil output the current Ip, and the output current I accurately reflects the magnitude and direction of the measured current. Since the magnetic core works in a zero-flux state, the linearity and remanence of the magnetic core have no effect on the accuracy of the sensor, so the Hall closed-loop sensor has high accuracy and small nonlinear distortion.

Hall closed-loop current sensor diagram

Technical features:

- Frequency bandwidth - high measurement accuracy

- fast response - low temperature drift

- Very good nonlinear distortion. No insertion loss

Introduction to CM9A

Domestic current sensor - CM9A H00 series is a new closed-loop (compensated) high-precision current sensor based on Hall principle launched by CHIPSENSE. There are currently two models: CHIPSENSE CM9A 1500 H00 and CHIPSENSE CM9A 3500 H00.

Product features

Insulation between primary and secondary sides

Raw materials comply with UL 94-V0

Excellent linearity

Exceptional accuracy

Low temperature drift

No insertion loss

Execution standards:

IEC 60664-1:2020

IEC 61800-5-1:2022

IEC 6 2109-1: 2010

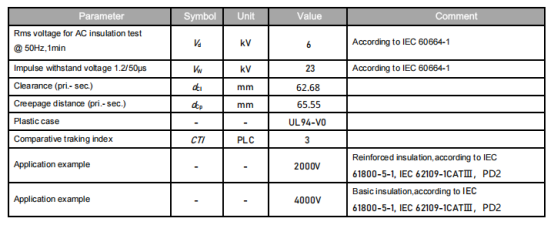

Insulation coordination

Parameter characteristics:

Power supply voltage: ± 15V~ ± 24V

Measuring range: ± 2250~ ± 4500A

Working range: -40~ 85 ° C

Accuracy: ± 0.3%

Response time: < 1μs

Insulation voltage: 6kV

Transient withstand voltage: 23kV

Bandwidth: > 100kHz

Linearity: 0.1%

From the above parameters and characteristics, it can be seen that this sensor of CHIPSENSE sufficient to deal with the harsh environment of deep sea salt spray corrosion and high humidity. It can be installed and deployed in a wind energy inverter to monitor the IGBT current in real time to prevent overload breakdown. The sensor is 100% localized, the cost is 30% lower than that of imported brands, and the supply chain radius is shortened. CHIPSENE has saved a lot of costs for many customers.

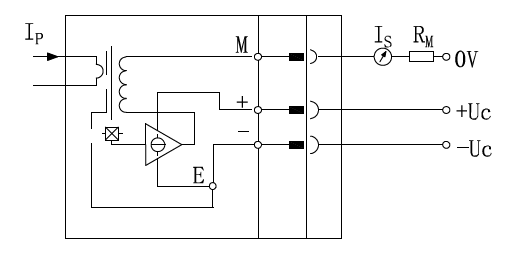

Wind energy inverter

Application circuit:

Conclusion:

The reason why floating wind power in our country is cheaper than fixed wind power, and the cost reduction speed is getting faster and faster. In 2021, the cost of the Three Gorges Leading Number 35,000 yuan/kW, and the Yangjiang project in 2025 has dropped to 22,000 yuan/kW, a decrease of 37%., Thanks to the collaborative cost reduction of the whole industry chain. From blades to generators, to IGBT chips, sensor chips and other core components are 100% localized, and the delivery cycle is greatly shortened. CHIPSENSE current sensor has also made corresponding improvements and contributions.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806